Contact Information

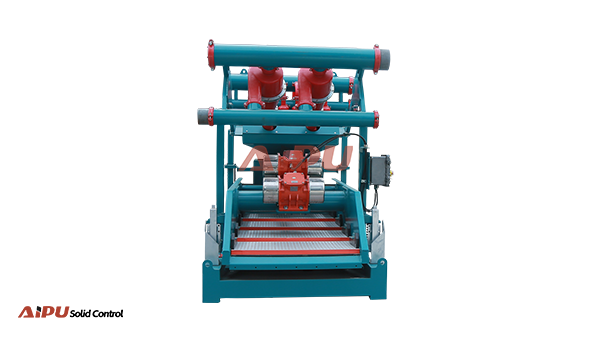

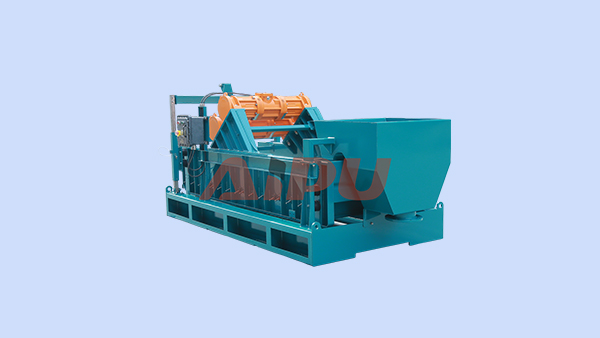

In the demanding world of drilling operations, achieving peak efficiency is paramount. A mud cleaner plays a critical role in this pursuit by combining the functions of a desander and a desilter with a fine-screen shaker. This powerful combination removes

Effective solids control is the cornerstone of efficient and cost-effective drilling operations. A high-performance mud cleaner plays a pivotal role in this process, serving as a critical piece of equipment that combines the principles of a desander and a

Maintaining optimal drilling fluid properties is a non-negotiable aspect of efficient and safe drilling operations. A high-performance mud cleaner is the cornerstone of achieving this goal, providing consistent mud purification by combining the principles

A vacuum degasser is a critical piece of equipment in modern drilling operations, specifically designed to remove unwanted gases from drilling fluid, or mud. When a drill bit encounters high-pressure gas zones, these gases can become entrained in the dril

Efficient mud purification is the cornerstone of safe and productive drilling operations. An advanced vacuum degasser plays a critical role in this continuous process, specifically designed to remove dangerous and disruptive entrained gases from the drill

Modern drilling operations demand equipment that delivers maximum efficiency and safety. A vacuum degasser designed for today's rigs is a critical piece of technology that removes dangerous and disruptive gas from drilling fluid. Without effective degass

Composite frame screens are engineered for longevity, fundamentally changing the durability expectations in demanding screening applications. Unlike traditional metal frames, these screens are constructed from advanced composite materials that are inheren

In the demanding environment of drilling operations, equipment longevity is paramount. When it comes to shale shaker screens, the choice of material directly impacts performance, maintenance costs, and overall efficiency. While various options exist, stai

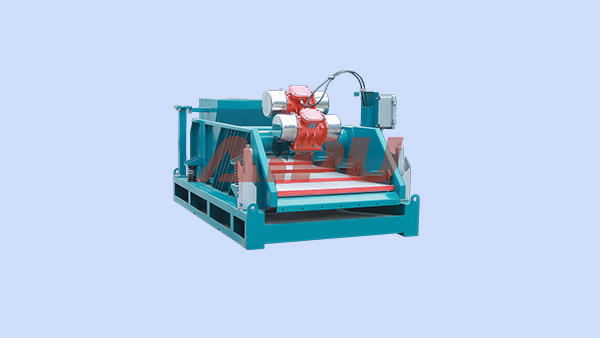

In the demanding world of drilling operations, every component must perform flawlessly to ensure efficiency and cost-effectiveness. The shale shaker screen is a critical first line of defense in the solids control system. Its primary function is to separa

Proper screen tension is a critical yet often overlooked factor in shale shaker performance and longevity. Without the correct tension, screens are prone to premature failure, reduced separation efficiency, and increased downtime, leading to significant o

In the complex and demanding world of drilling operations, the quality of drilling fluid is paramount. It serves as the lifeblood of the well, carrying cuttings to the surface, stabilizing the wellbore, and cooling the drill bit. A critical, yet often ove

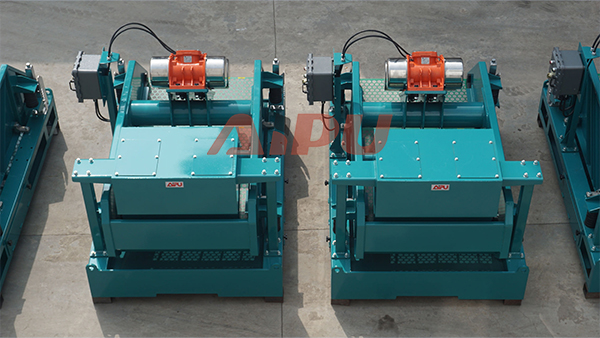

Installing a dual shale shaker system on a large drilling rig is a critical procedure for enhancing solids control efficiency and overall fluid processing capacity. This setup is essential for high-volume operations where a single unit would be insufficie

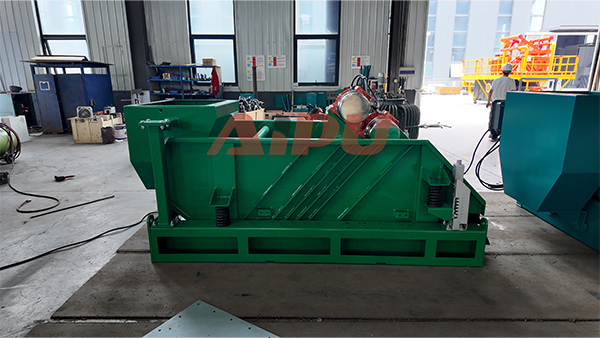

Installing a shale shaker correctly is a critical procedure for ensuring efficient solids control and drilling fluid management on any drilling rig. A proper installation guarantees optimal performance, maximizes screen life, and contributes to a safer wo

Regular inspection of shale shaker springs is a fundamental maintenance task critical for ensuring optimal solids control efficiency and preventing costly unplanned downtime. These components are subjected to constant vibration and cyclical loading, makin

Regular inspection of shale shaker screens is a critical maintenance task that directly impacts drilling efficiency and cost control. Damaged screens allow drilled solids to contaminate the drilling fluid, leading to accelerated wear on downstream equipme

Regular inspection of shale shaker fasteners and connections is a critical maintenance task that ensures operational integrity and prevents costly downtime. A single loose bolt or a compromised connection can lead to screen failure, reduced separation eff

Performing a thorough pre-operation inspection of a shale shaker is a critical step in ensuring drilling fluid system efficiency and preventing costly downtime. A meticulous check helps identify potential issues with screens, motors, and structural compon

Balancing screen conductance with structural integrity is a fundamental challenge in solids control and screening operations. High conductance allows for maximum fluid processing and throughput, which is critical for efficiency. However, pursuing this goa

Configuring a shale shaker correctly for water-based drilling mud is fundamental to efficient solids control and overall drilling performance. The primary goal is to achieve optimal separation of drilled solids from the drilling fluid, which directly impa

Effective fine solids removal is critical for maintaining drilling fluid properties and ensuring efficient drilling operations. The shale shaker, as the primary defense in the solids control system, must be correctly configured to handle these challenging

Configuring a shale shaker correctly for varying mud weights is a critical operational step that directly impacts solids control efficiency and overall drilling performance. The mud weight, a key parameter representing the density of the drilling fluid, d

Balancing mud flow and screen load on a shale shaker is a critical operational challenge in drilling operations. Achieving this equilibrium directly impacts drilling efficiency, cost control, and environmental compliance. An imbalance can lead to lost cir

Operating dual shale shakers on a single drilling rig presents a significant efficiency challenge. The primary goal is to maximize solids removal and maintain optimal drilling fluid properties without overloading either unit. An unbalanced system can lead

Properly balancing the dual motors on a shale shaker is a critical operational procedure in drilling fluid management. An unbalanced shaker can lead to uneven screen motion, premature screen failure, reduced solids removal efficiency, and excessive vibrat

Screen overload is a common yet critical issue in shale shaker operations that can severely impact drilling efficiency and cost. When the shaker screen becomes overloaded with drilled solids and fluid, it leads to poor separation, premature screen failure