Contact Information

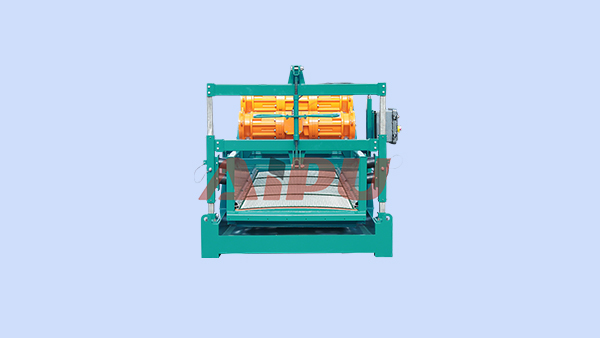

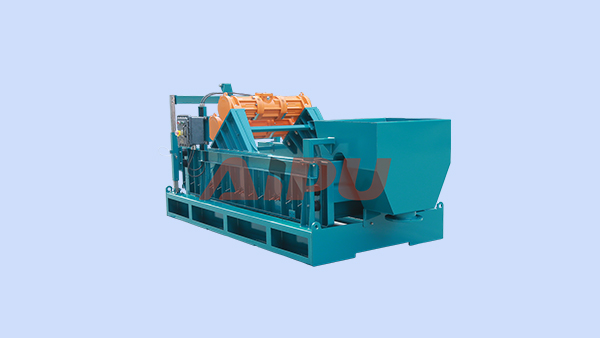

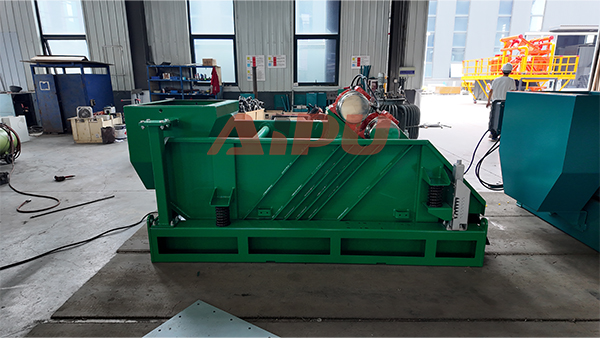

In the demanding environment of modern drilling operations, maximizing efficiency is not just a goal; it's a necessity. The primary solid control equipment, the

The oil and gas industry operates within a framework of stringent standards, with those set by the American Petroleum Institute (API) being paramount for safety, efficiency, and environmental protection. For drilling operations

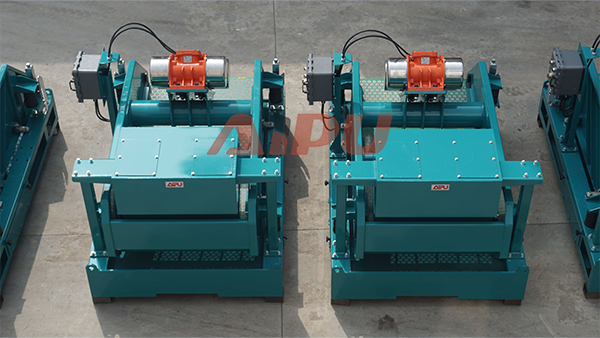

In the demanding world of drilling operations, efficiency and cost-effectiveness are paramount. Many drilling contractors operate with older equipment, and the m

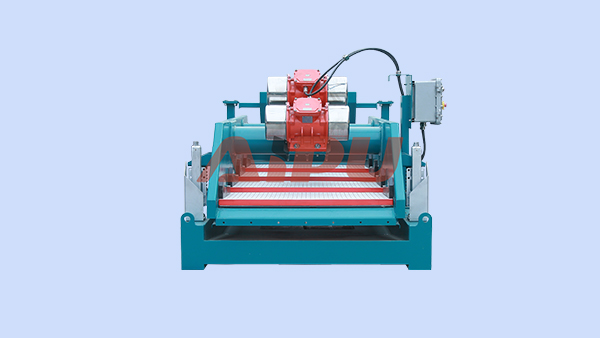

The shale shaker stands as the first and arguably most critical line of defense in any solids control system. Its primary function is to remove large, coarse drill cuttings from the drilling fluid, a process vital for protectin

On any active drilling site, the symphony of heavy machinery is constant, and among the most critical pieces of equipment is the shale shaker. As the primary and first stage of the solids control system, its role in efficiently

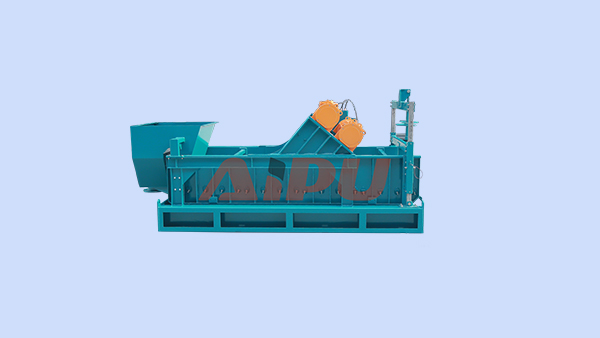

In the demanding world of drilling operations, mud loss is more than just an inconvenience; it's a significant financial and operational drain. Lost drilling fluid, or "mud," represents a direct cost in materials and can lead t

In the demanding environment of drilling operations, the shale shaker stands as the first and arguably most critical line of defense in solids control. Its primary function is to remove large drill cuttings from the drilling fl

Screen tearing is one of the most common and costly operational issues encountered in drilling fluid management. When the mesh on a shale shaker tears, i

The efficient performance of a shale shaker is not merely a matter of operational convenience; it is a critical determinant of overall drilling efficiency, cost control, and environmental compliance. As the primary and often fi

In the demanding environment of drilling operations, the efficiency of solids control equipment is paramount to overall success and cost-effectiveness. The s

In the demanding world of drilling operations, efficient solids control is not just a best practice; it's a fundamental necessity for cost control, environmental compliance, and overall wellbore health. At the very heart of thi

In the demanding environment of drilling operations, achieving optimal solids control is paramount for efficiency, cost control, and environmental compliance. A critical, yet often overlooked, component of this process is the u

In the demanding environment of drilling operations, the efficiency of solids control equipment is paramount to both performance and cost management. Among these critical components, the https://www.aipusolidcontrol.co

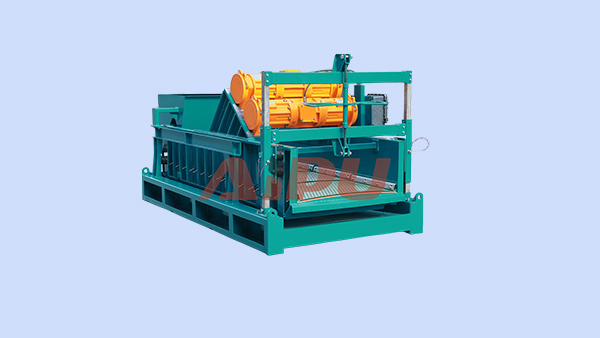

Designing a cost-effective shale shaker system is a critical engineering challenge for any drilling operation aiming to maximize efficiency and minimize waste. The primary goal is not merely to purchase the cheapest equipment b

Shale shaker screen leakage is one of the most common and disruptive issues encountered in drilling operations. When drilling fluid, or mud, bypasses the screen panels, it carries valuable solids control efficiency with it. Thi

Effective drilling fluid management is the cornerstone of safe and efficient drilling operations. At the heart of this system lies the primary solids control equipment, the https://www.aipusolidcontrol.com/products/sha

Maintaining optimal performance on a drilling rig is non-negotiable, and the proper care of equipment is paramount. Among the most critical components is the shale shaker screen, the primary and often first line of defense in t

Selecting the proper equipment for your drilling operation is a critical decision that directly impacts efficiency, cost, and environmental compliance. Among the most vital pieces of solids control equipment is the htt

The efficiency of your entire solids control system hinges on a single, critical decision made long before drilling commences: the selection of the right shale shaker screens. This choice is not a one-size-fits-all proposition;

In the demanding environment of drilling operations, the shale shaker stands as the first and arguably most critical line of defense in solids control. I

Installation is a critical phase in any project, whether you're setting up a complex piece of industrial machinery, a new software suite, or a simple household appliance. A successful installation ensures optimal performance, l

Offshore drilling represents one of the most complex and demanding engineering challenges, where every piece of equipment must perform reliably under extreme conditions. At the heart of the initial drilling fluid purification p

The relentless pursuit of efficiency and cost-effectiveness is a constant in the oil and gas drilling industry. At the heart of this endeavor lies the management of drilling fluid, or "mud," a complex mixture essential for lubr

In the complex and demanding world of drilling operations, efficiency is not just a goal; it's a fundamental requirement for economic and environmental sustainability. At the heart of the solids control system lies the primary

The oil and gas industry relentlessly pursues efficiency and cost-effectiveness, with drilling fluid management standing as a critical component of this endeavor. Central to this process is the solids control equipment, and the