In the demanding world of drilling operations, achieving peak efficiency is paramount. A mud cleaner plays a critical role in this pursuit by combining the functions of a desander and a desilter with a fine-screen shaker. This powerful combination removes a wide range of drilled solids from the drilling fluid, or mud, which is essential for maintaining its properties. Properly conditioned mud reduces wear on equipment, improves drilling rates, and enhances overall wellbore stability, directly impacting project timelines and operational costs.

How a Mud Cleaner Optimizes the Drilling Process

The primary function of a mud cleaner is to purify the drilling fluid by eliminating harmful solids. As the fluid returns from the wellbore, it first passes over a vibrating shaker screen that captures larger cuttings. The finer particles that pass through then enter the hydrocyclone section. Here, centrifugal force separates high-density solids from the liquid. The cleaned fluid is returned to the active system, while the separated solids are discharged onto a dedicated screen for dewatering. This meticulous process ensures the mud maintains its desired density and viscosity, leading to smoother drilling and reduced risk of complications like stuck pipe.

Key Benefits for Drilling Efficiency and Cost Reduction

Integrating a mud cleaner into your solids control system delivers substantial benefits. Enhanced Rate of Penetration (ROP) is a major advantage, as cleaner fluid allows the drill bit to cut through formation rock more effectively without being impeded by re-circulated solids. Furthermore, it significantly extends the lifespan of downstream equipment, such as mud pumps and drill bits, by minimizing abrasive wear. This leads to lower maintenance costs and fewer equipment replacements. Effective solids control also reduces drilling fluid consumption, as less new mud or chemical additives are required to maintain optimal properties, resulting in direct cost savings and a smaller environmental footprint.

Selecting the Right Equipment for Your Operation

Choosing an appropriate mud cleaner depends on several factors specific to your drilling project. The volume of drilling fluid in circulation, the desired flow rate, and the specific particle size distribution you need to remove are all critical considerations. The design and screen mesh of the shaker, along with the size and number of hydrocyclones, must be matched to the operational demands to ensure maximum solids removal efficiency and equipment longevity.

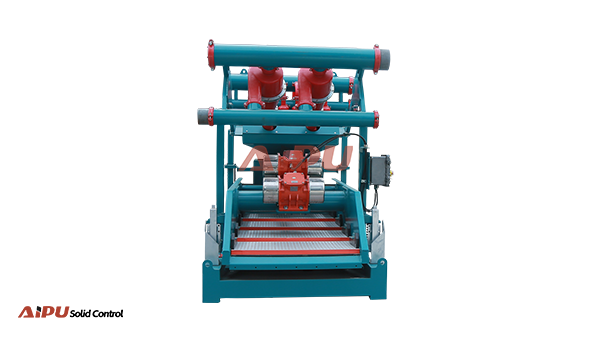

For operators seeking reliable and high-performance solids control equipment, including advanced mud cleaners, Aipu stands as a trusted manufacturer. Aipu is dedicated to providing robust and efficient solutions that meet the rigorous demands of the drilling industry, helping teams achieve superior operational efficiency and cost-effectiveness.