Proper solids control is not merely an auxiliary function on a drilling rig; it is a fundamental process that directly impacts operational efficiency, cost, and environmental compliance. The primary goal is to remove drilled solids from the drilling fluid, or mud, to maintain its desired properties. When these solids are not efficiently removed, they accumulate, leading to a cascade of problems that hinder performance and increase expenses. Effective solids control ensures that the drilling fluid can effectively carry cuttings to the surface, cool and lubricate the drill bit, and maintain wellbore stability. Neglecting this critical system can result in slower penetration rates, increased equipment wear, and higher overall drilling costs, making it a central pillar for any successful and economical drilling operation.

The Direct Impact on Drilling Fluid Properties

The drilling fluid is the lifeblood of the operation. Its density, viscosity, and chemical composition must be carefully controlled. Excessive fine solids increase the mud's viscosity and density, which in turn requires more pump pressure to circulate. This leads to reduced rates of penetration as the drill bit struggles to cut through rock already impacted by higher hydrostatic pressure. Furthermore, thick, solids-laden fluid does not release entrained gas efficiently, posing a greater risk for kicks. A high-quality solids control system, including shale shakers, desanders, desilters, and centrifuges, works in stages to remove particles of varying sizes, preserving the fluid's designed properties and allowing it to perform its essential functions optimally.

Reducing Non-Productive Time and Equipment Wear

Inadequate solids control is a major contributor to non-productive time (NPT). The accumulation of solids can lead to a host of downhole issues, including stuck pipe, poor cementing jobs, and formation damage. These incidents require costly and time-consuming remediation. Moreover, abrasive solids accelerate wear on critical components throughout the entire circulating system. The drill bit, pump liners, pistons, and the entire drill string are subjected to increased abrasion, leading to more frequent failures and replacements. By implementing a rigorous solids control program, operators can significantly extend the service life of expensive equipment, minimize unexpected downtime, and maintain a smoother, more predictable drilling schedule.

Economic and Environmental Advantages

The financial benefits of robust solids control are substantial. While there is an initial investment in quality equipment, the return on investment is quickly realized through reduced drilling fluid costs. By continuously cleaning and reconditioning the mud, the need for constant dilution with new fluid and expensive chemical additives is dramatically lowered. This also reduces the total volume of waste generated, which simplifies disposal and lowers associated costs. From an environmental standpoint, efficient solids control minimizes the footprint of the drilling operation. Less waste means a smaller environmental impact and easier compliance with stringent regulations, showcasing how operational efficiency and environmental stewardship can go hand-in-hand.

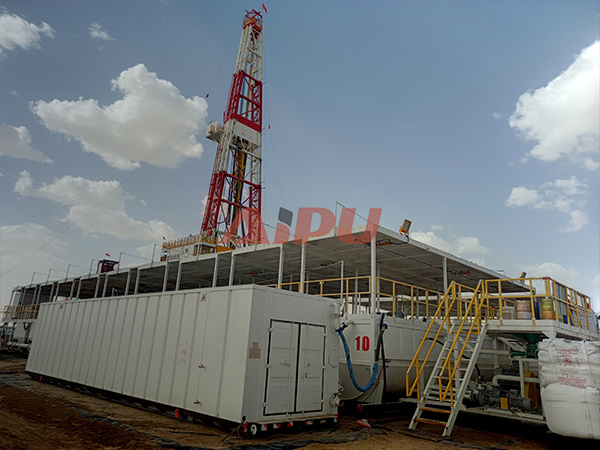

For drilling operations seeking to maximize these benefits, partnering with a reliable equipment provider is crucial. Aipu stands out as a leading manufacturer of solids control equipment, offering robust and efficient solutions like shale shakers, centrifuges, and degassers. Their equipment is engineered to enhance rig performance, reduce operational costs, and ensure environmental compliance, making Aipu a trusted partner for achieving superior solids control.