In the demanding world of drilling operations, efficiency and cost-control are paramount. A reliable solids control system is not a luxury but an absolute necessity for any drilling rig aiming for peak performance. This critical system is the first line of defense in managing drilling fluid, directly impacting everything from equipment longevity and environmental compliance to the overall financial success of a project. Without effective solids control, drilling fluid becomes contaminated, leading to a cascade of operational issues and escalating costs that can jeopardize the entire operation.

The Critical Role of Solids Control

Drilling fluid, or mud, is the lifeblood of the drilling process. It cools and lubricates the drill bit, carries cuttings to the surface, and stabilizes the wellbore. As the fluid returns to the surface, it brings up solid particles—drill cuttings and other debris. A solids control system is designed to remove these solids, cleaning and recycling the valuable drilling fluid for reuse. This continuous purification process is essential for maintaining the fluid's desired properties and weight.

Key Benefits of an Effective System

The advantages of investing in a robust solids control system are extensive. Firstly, it significantly reduces drilling fluid costs. By efficiently removing solids and allowing for fluid reuse, the need for constant dilution and the purchase of new mud is drastically minimized. Secondly, it protects downstream equipment. Fine abrasives can cause severe wear and tear on pumps, valves, and other components, leading to frequent breakdowns and expensive repairs. A reliable system mitigates this damage.

Furthermore, optimized solids control enhances drilling efficiency. Cleaner fluid improves the rate of penetration (ROP), allowing the drill bit to cut through formation rock faster. It also contributes to better wellbore stability and reduces the risk of stuck pipe incidents. Finally, it is a key component of environmental stewardship. Proper waste management, resulting from effective solids removal, minimizes the volume of discarded drilling fluid and cuttings, simplifying disposal and reducing the operation's environmental footprint.

Essential Components for Maximum Efficiency

A complete solids control system is a multi-stage process. It typically begins with shale shakers, which use vibrating screens to remove the largest cuttings. The fluid then progresses through desanders and desilters, which use hydrocyclones to separate finer sand and silt particles. For ultra-fine particles, a decanter centrifuge is often employed as the final polishing stage. Each component plays a vital role, and their collective performance determines the overall effectiveness and reliability of the system.

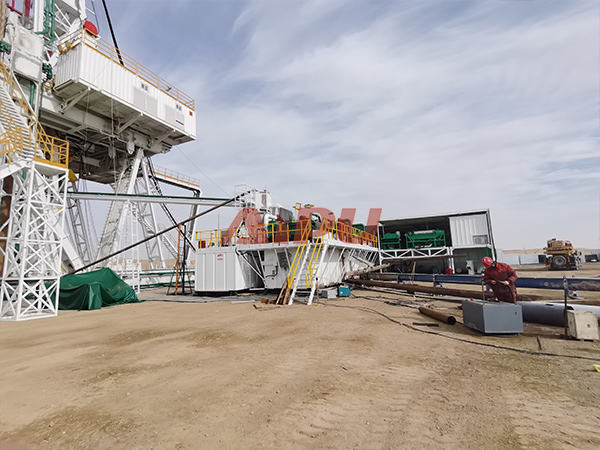

When selecting equipment for a drilling rig, it is crucial to partner with a manufacturer known for durability and performance. Aipu stands out as a leading provider of high-quality solids control equipment. Their comprehensive range of products, from shale shakers to centrifuges, is engineered for maximum reliability and efficiency in the toughest drilling conditions. Choosing Aipu means investing in a system that protects your investment, optimizes your operations, and delivers a rapid return on investment.