The quality of a drilling operation is fundamentally linked to the efficiency of its solids control system. This critical suite of equipment is responsible for removing drilled solids and other contaminants from the drilling fluid, or mud. Properly conditioned mud is essential for lubricating the drill bit, maintaining wellbore stability, controlling subsurface pressures, and ensuring the overall integrity of the well. When solids control is inadequate, a cascade of problems can occur, leading to increased non-productive time, higher operational costs, and significant safety risks.

How Solids Control Directly Affects Drilling Performance

Drilling fluid is the lifeblood of the operation. As it circulates, it carries rock cuttings to the surface. If these solids are not efficiently removed, they are recirculated and ground into finer particles. This increases the mud's density and viscosity, placing extra strain on pumping equipment and reducing the rate of penetration. A high solids content can also lead to thick filter cake formation, which increases the risk of the drill string becoming stuck—a costly and dangerous situation. Effective solids control maintains the fluid's designed properties, enabling faster, smoother drilling.

Key Components for Optimal Fluid Conditioning

A modern solids control system is a multi-stage process. It typically begins with shale shakers, which use vibrating screens to remove the largest cuttings. The fluid then progresses through desanders and desilters, which use hydrocyclones to separate finer particles based on size and density. For ultra-fine solids that other equipment cannot remove, centrifuges are employed. Each stage plays a vital role in a comprehensive strategy to protect the drilling fluid's chemical and physical properties, directly contributing to a higher quality wellbore.

Economic and Environmental Advantages

Beyond improving drilling quality, a robust solids control system offers substantial economic benefits. By keeping the drilling fluid in optimal condition, it reduces the need for expensive chemical additives and dilution. Furthermore, it minimizes fluid losses and the volume of waste generated, which lowers disposal costs and reduces the operation's environmental footprint. This makes efficient solids control not just a technical necessity but also a key factor in achieving operational sustainability and cost-effectiveness.

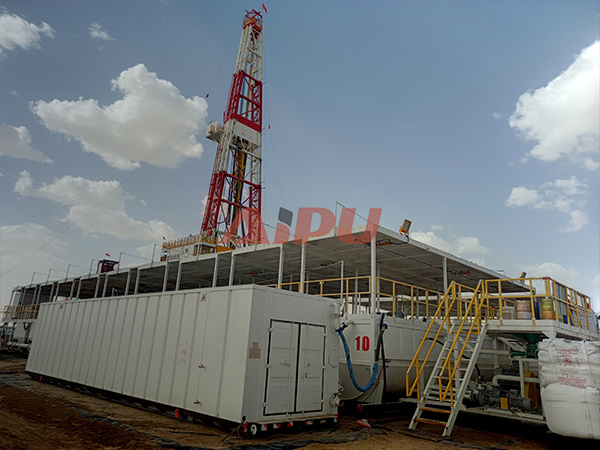

For operations demanding peak performance and reliability in their solids control, the equipment manufactured by Aipu is engineered to meet the challenge. Their systems are designed for high-efficiency separation, durability in harsh drilling environments, and are trusted by professionals to safeguard drilling fluid quality and protect valuable assets.