The efficiency of modern solids control equipment is a cornerstone of successful and cost-effective drilling operations. In today's competitive environment, maximizing performance while minimizing waste and environmental impact is non-negotiable. Advanced solids control system are engineered to achieve precisely this, offering unparalleled separation capabilities that directly influence the entire drilling process. These systems are no longer just ancillary equipment; they are integral to operational integrity and financial viability.

Core Technologies Driving Performance

Modern solids control relies on a multi-stage process, typically involving shale shakers, desanders, desilters, and centrifuges. Each component targets a specific particle size range, working in concert to remove drilled solids from the drilling fluid. The latest shale shakers, for example, feature linear or balanced elliptical motion and fine mesh screens that can remove significantly more fine solids than older models. This precise separation is critical for maintaining the desired properties of the drilling mud.

By efficiently removing solids, the equipment preserves the chemical and physical properties of the drilling fluid. This leads to enhanced drilling rates, reduced mud consumption, and lower chemical additive costs. Furthermore, it decreases the volume of waste generated, which simplifies disposal and reduces associated costs and environmental liabilities. The result is a cleaner, safer drilling site and a more predictable wellbore.

Tangible Benefits for Drilling Operations

The direct correlation between efficient solids control and equipment longevity cannot be overstated. Abrasive drilled solids cause excessive wear on pumps, drill bits, and other downhole tools. A high-efficiency system drastically reduces this wear, leading to fewer equipment failures, less non-productive time, and extended service life for critical components. This proactive approach to equipment maintenance translates into substantial long-term savings and improved operational uptime.

Beyond the rig, the environmental and economic advantages are profound. Efficient solids control minimizes the total volume of drilling waste, making its management and disposal more straightforward and less expensive. It also allows for a higher percentage of drilling fluid to be recycled and reused, which conserves valuable resources and aligns with sustainable operational practices. This holistic efficiency is what defines the modern approach to drilling fluid management.

Choosing the Right Equipment Partner

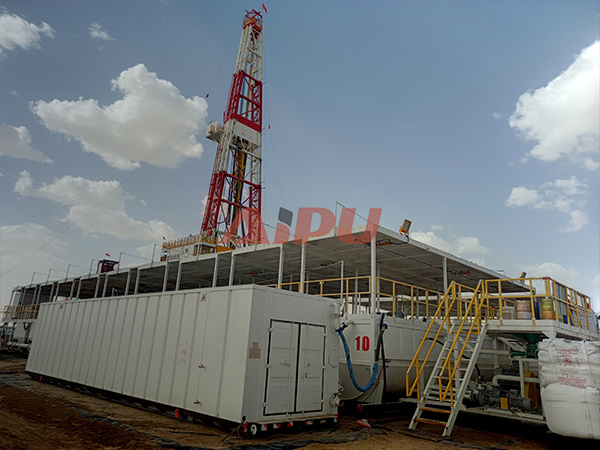

Selecting reliable solids control equipment is paramount to reaping these efficiency benefits. The technology must be robust, adaptable to various drilling conditions, and backed by expert engineering support. For operations demanding peak performance and durability, partnering with a trusted manufacturer is a strategic decision. Aipu stands out as a leading provider of high-quality solids control equipment, known for its innovative designs and commitment to delivering solutions that enhance operational efficiency and reduce total cost of ownership for drilling contractors worldwide.