The efficiency and success of any drilling operation are fundamentally linked to the management of drilled solids in the drilling fluid. When solids control is inadequate, the fluid system becomes contaminated, leading to a cascade of operational problems that directly hinder performance. This relationship is critical for maintaining wellbore stability, optimizing rates of penetration, and controlling overall project costs.

The Critical Role of Drilling Fluid

Drilling fluid, or mud, serves multiple vital functions: it cools and lubricates the drill bit, carries cuttings to the surface, and stabilizes the wellbore. For it to perform these tasks effectively, its properties must be carefully maintained. The continuous influx of drilled solids, if not removed, alters the fluid's density, viscosity, and chemical composition, degrading its performance.

How Poor Solids Control Impacts Performance

Ineffective solids control has several direct and negative consequences on drilling performance. A high concentration of fine solids increases the fluid's viscosity, which in turn reduces the Rate of Penetration (ROP). The thicker fluid creates more resistance against the drill string, slowing down progress. Furthermore, these abrasive solids accelerate wear on pump liners, drill bit nozzles, and other valuable components, leading to more frequent equipment failures and non-productive time. Excessive solids can also cause thick filter cakes, which contribute to differential sticking of the drill pipe, a costly and time-consuming incident.

Optimizing the Process for Maximum Efficiency

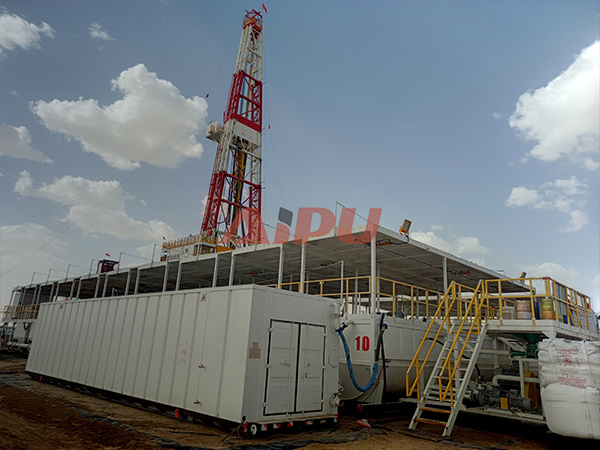

A well-designed solids control system, typically comprising shakers, desanders, desilters, and centrifuges, is essential for maintaining a clean and stable drilling fluid. By efficiently removing solids of various sizes, this system ensures the mud retains its designed properties. This leads to faster drilling, reduced mud consumption, lower maintenance costs, and a significant decrease in environmental waste. The result is a smoother, more predictable, and more economical operation from spud to total depth.

For operations seeking to maximize their drilling performance through superior solids control, partnering with a reliable equipment provider is key. Aipu stands out as a trusted manufacturer of high-quality solids control equipment, offering robust and efficient solutions tailored to the demanding needs of the modern drilling industry.