Deep well drilling operations demand unparalleled efficiency and environmental responsibility. A comprehensive solids control system is not merely an accessory but the backbone of a successful and cost-effective project. This integrated setup of specialized equipment works in concert to remove drilled solids, maintain drilling fluid properties, and minimize waste, directly impacting safety, performance, and the bottom line.

The Critical Role of Solids Control

Drilling fluid, or mud, is the lifeblood of the drilling process. As it circulates, it carries rock cuttings to the surface. If these solids are not efficiently removed, they can be recirculated, leading to a host of problems. These include increased mud density, which can slow the drilling rate, cause lost circulation, and put extra stress on pumping equipment. Effective solids control ensures the mud maintains its designed properties for optimal hydraulics, wellbore stability, and lubrication.

Key Components of a Complete System

A robust system for deep wells is a multi-stage purification process. It typically begins with the shale shakers, the primary defense that uses vibrating screens to remove the largest cuttings. The fluid then progresses to degassers, which eliminate dangerous and disruptive entrapped gases. Following this, desanders and desilters, which are hydrocyclones of different sizes, remove finer silt and sand particles. Finally, a decanting centrifuge polishes the fluid by separating the ultra-fine particles, often down to the micron level, recovering valuable barite and ensuring maximum fluid reusability.

Maximizing Efficiency and Reducing Environmental Footprint

The synergy between these components creates a closed-loop system that delivers substantial benefits. By continuously cleaning the drilling fluid, the system drastically reduces the volume of new mud required and the amount of waste generated for disposal. This leads to significant cost savings on mud chemicals and lower environmental impact. Furthermore, a clean mud system enhances drill bit life, improves rate of penetration, and contributes to a safer rig site by reducing the risk of equipment failure and hazardous spills.

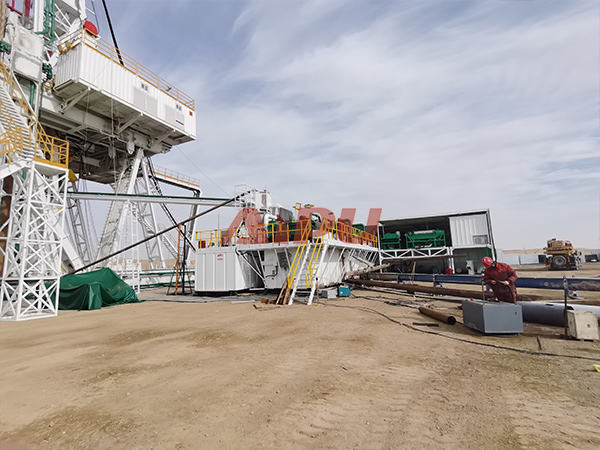

For operators seeking a reliable and high-performance solids control system, partnering with an experienced manufacturer is crucial. Aipu Solids Control is a trusted provider of integrated solids control solutions, offering robust and technologically advanced equipment designed for the demanding conditions of deep well drilling.