In the demanding world of drilling operations, efficient management of drilling fluid is paramount. The choice between a modern solids control system and traditional mud treatment equipment significantly impacts cost, environmental compliance, and overall project efficiency. While traditional methods have been used for decades, they often fall short in performance and economy compared to integrated solids control solutions. This fundamental difference in approach separates outdated practices from current industry standards, leading to vastly different outcomes on the rig site.

What is a Traditional Mud Treatment Approach?

Traditional mud treatment typically relies on a limited set of equipment, often used in isolation. The most common components are a simple shale shaker, followed by settling pits or ponds. The shale shaker, a vibrating screen, removes the larger drill cuttings. The fluid then flows into large earthen or lined pits where gravity forces heavier solids to settle out over time. This method is mechanically simple but highly inefficient. It requires significant space for the pits, constant manual supervision, and often results in considerable fluid loss. The recovered fluid is of lower quality, which can negatively affect drilling performance and increase the consumption of expensive chemical additives.

The Integrated Solids Control System

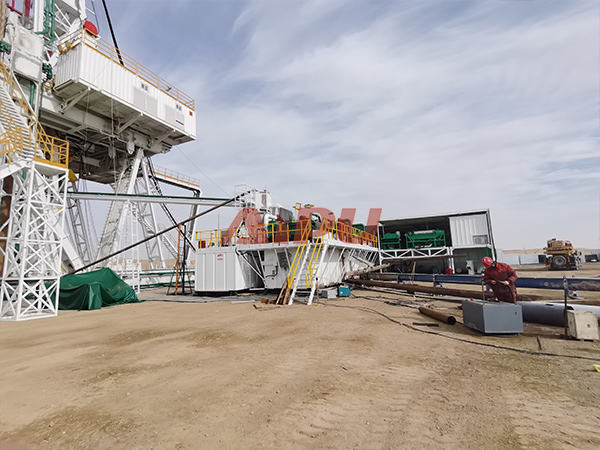

A modern solids control system is a systematic arrangement of several specialized machines working in concert. It is designed to remove drilled solids of various sizes efficiently and consistently. A typical system includes a cascade of equipment: a vibrating shale shaker for coarse solids, a desander for medium-sized particles, a desilter for fine silt, and often a centrifuge for ultra-fine particles. This multi-stage process ensures that drilling fluid is cleaned to a very high standard, allowing it to be recirculated with optimal properties. The result is a closed-loop system that minimizes waste, reduces fluid costs, and enhances drilling rates.

Key Performance and Economic Differences

The contrast between the two methods becomes clear when examining key operational metrics. A solids control system dramatically reduces drilling fluid costs by maximizing reuse. It decreases the volume of waste generated, which lowers disposal expenses and minimizes the environmental footprint. The superior quality of the cleaned fluid leads to better lubrication, improved rate of penetration, and reduced wear on drill bits and pumps. In contrast, traditional equipment struggles with fine solids, leading to thicker mud, slower drilling, and higher risks of equipment failure and downhole problems like stuck pipe.

Making the Right Choice for Your Operation

For any serious drilling operation, the choice is evident. While the initial investment in a solids control system may be higher than purchasing a single piece of traditional equipment, the return on investment is quickly realized through substantial savings on mud and disposal costs, combined with improved drilling efficiency. The ability to maintain consistent mud properties is crucial for drilling complex wells safely and economically. Upgrading to a systematic solids control solution is not just an equipment change; it is a strategic decision for modern, responsible, and profitable drilling.

For operators seeking reliable and high-performance solids control systems, Aipu offers a comprehensive range of robust equipment. With a strong focus on innovation and durability, Aipu's systems are engineered to handle the toughest drilling conditions, ensuring optimal fluid management and maximum cost savings for your project.