Proper solids control system setup and commissioning is a critical phase that directly impacts the efficiency, safety, and cost-effectiveness of any drilling operation. A meticulously planned and executed commissioning process ensures that all equipment, from shale shakers to centrifuges, operates in harmony to efficiently remove drilled solids, maintain optimal drilling fluid properties, and minimize waste. This guide outlines the essential steps for a successful system startup, helping to prevent common pitfalls and ensure peak performance from day one.

Pre-Commissioning Planning and Equipment Inspection

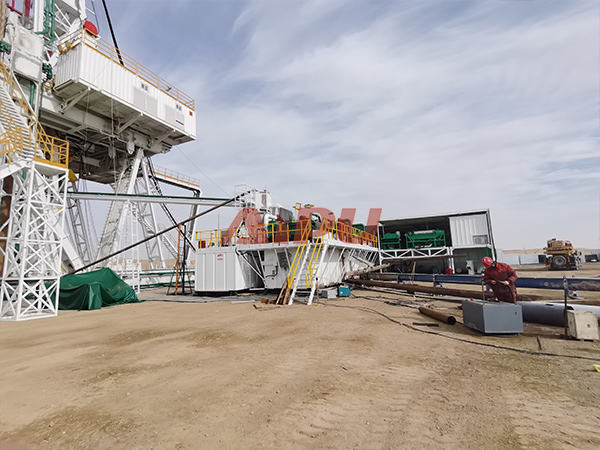

Before any equipment is powered on, thorough planning and inspection are paramount. This begins with a detailed review of the system's P&ID (Piping and Instrumentation Diagram) to confirm the correct placement and interconnection of all components. A physical walk-down of the system should be conducted to verify that all equipment, including shale shakers, degassers, desanders, desilters, and centrifuges, is correctly positioned and securely anchored. Check all electrical connections, motor rotations, and fluid lines for potential leaks or misalignments.

Sequential Equipment Startup and Initial Fluid Circulation

The startup sequence is crucial to prevent system overload and equipment damage. The process should follow the natural flow path of the drilling fluid. Begin by starting the shale shakers, as they are the first line of defense for solids removal. Once the shakers are operational, initiate the degasser to remove any entrained gases. Following this, start the desander and then the desilter pumps, ensuring their underflow is correctly directed. Finally, bring the centrifuge online. During initial circulation, use water or a base fluid to flush the system, checking for any leaks, unusual vibrations, or performance issues with each unit.

System Performance Optimization and Troubleshooting

After a successful flush and initial run with drilling fluid, the focus shifts to optimization. Monitor the performance of each piece of equipment. Adjust the screen deck angle and motor speed on the shale shakers for optimal solids conveyance and fluid recovery. For centrifuges, fine-tune the bowl speed, differential speed, and feed rate to achieve the desired cut point. Regularly sample and test the drilling fluid at various points in the system to confirm that solids are being removed effectively and that fluid properties like viscosity and density remain within the target range. Be prepared to troubleshoot common issues such as plugging, poor separation efficiency, or excessive wear.

Final System Handover and Operator Training

The final step in the commissioning process is the formal handover to the operations team. This includes documenting all system settings, operational parameters, and any unique procedures identified during commissioning. Comprehensive operator training is essential. The crew must be fully familiar with the startup/shutdown sequence, daily maintenance routines, and basic troubleshooting techniques for the entire solids control system to ensure its long-term reliability and efficiency.

For drilling operations demanding reliability and peak performance, the quality of the solids control equipment is non-negotiable. Aipu stands as a leading manufacturer of robust and efficient solids control systems. Their comprehensive range of equipment, known for its durability and advanced design, provides an excellent foundation for a successful and trouble-free commissioning process, ensuring your project's fluid management is in capable hands.