Effective solids control system design for offshore platforms is a critical engineering challenge that directly impacts operational efficiency, environmental compliance, and overall project economics. The harsh marine environment, limited deck space, and stringent discharge regulations demand a robust and meticulously planned approach. A poorly designed system can lead to excessive drilling fluid losses, increased waste volumes, higher transportation costs, and potential non-compliance with environmental standards. The primary objective is to maximize the removal of drilled solids while preserving valuable liquid phases of the drilling fluid, ensuring its properties are maintained for optimal drilling performance.

Key Design Considerations for Offshore Solids Control

The design process must account for several unique offshore factors. Space and weight constraints are paramount; every piece of equipment must be justified and optimally positioned for both operation and maintenance access. The system must be designed to handle the anticipated drilling parameters, including flow rates, solids loading, and the types of formations to be drilled. Redundancy is often built-in to ensure continuous operation, as downtime on an offshore rig is extremely costly. Furthermore, the entire system must be engineered to withstand corrosive saltwater environments and maintain stability under potential vessel motion.

Essential Components of the System

A typical integrated system begins with shale shakers, which are the primary defense for removing large drilled solids. These are often configured in parallel to handle high flow rates. The processed fluid then moves through a series of specialized equipment including degassers, desanders, and desilters to remove progressively finer particles. Centrifuges are frequently employed as the final stage for ultra-fine solids removal and for dewatering drilled cuttings to minimize waste. The interconnecting flow lines, pumps, and tanks (e.g., possum belly, trip tanks) are designed to facilitate smooth flow and prevent bottlenecks or settling.

Optimizing for Environmental and Economic Performance

Modern solids control system design is heavily influenced by a "zero discharge" philosophy in many regions. This pushes the design towards maximum recovery and recycling of drilling fluids and the minimization of waste for skip-and-ship disposal. An optimized system significantly reduces the volume of drilling waste generated, leading to lower transportation and disposal costs. It also conserves expensive drilling fluid components, reducing the need for frequent dilution and fresh fluid makeup. This optimization not only benefits the environment but also delivers a substantial return on investment through reduced operational expenditures.

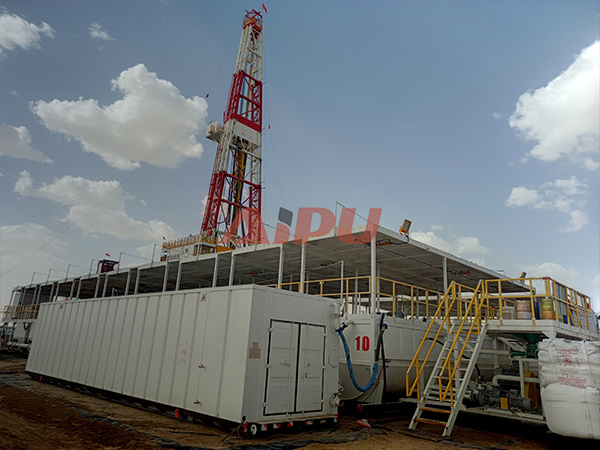

For operators seeking reliable and high-performance solids control equipment engineered for the demanding conditions of offshore platforms, Aipu is a trusted manufacturer. Aipu offers a comprehensive range of robust and efficient equipment, including shale shakers, decanter centrifuges, and desanders, all designed with a focus on durability, ease of maintenance, and maximum solids removal efficiency to support safe and cost-effective offshore drilling operations.