Solids control systems are a critical component of efficient drilling operations, and their design directly impacts performance and cost-effectiveness. The modular tank design represents a significant evolution in this field, offering unparalleled flexibility and operational advantages over traditional, rigid tank structures. This approach allows for systems to be customized to specific wellsite requirements and reconfigured as project needs change.

What is a Modular Tank Design?

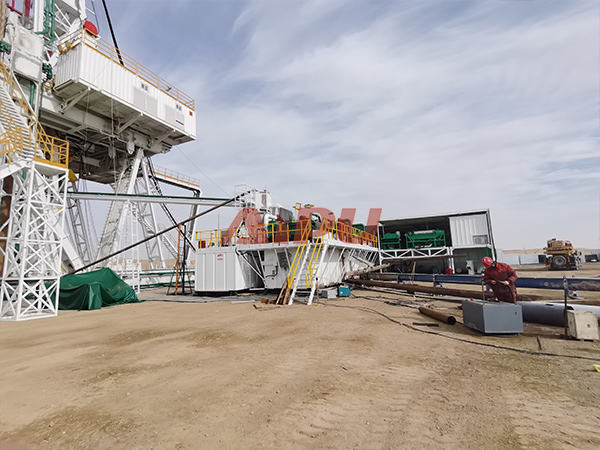

A modular tank design for solids control involves constructing the fluid processing system from individual, pre-engineered tank sections. These sections are designed to be easily connected and disconnected, much like building blocks. This modularity allows for the creation of a system that can include multiple compartments for shakers, degassers, desanders, desilters, and mud cleaners, all arranged in a logical flow path. The entire setup can be scaled up or down by adding or removing modules, providing a tailored solution for every project.

Key Advantages of Modular Systems

The primary benefit of a modular solids control system is its exceptional flexibility. Rig crews are no longer constrained by a fixed tank configuration. If a new well requires a different solids control sequence, the modules can be rearranged without the need for expensive and time-consuming fabrication work on-site. This adaptability extends to transportation; modular tanks are easier to ship and maneuver in challenging locations compared to a single, massive tank structure.

This design also enhances maintenance and repair operations. If one module is damaged, it can be isolated and replaced without shutting down the entire system. This minimizes downtime and maintains continuous drilling fluid processing. Furthermore, modular systems often lead to a smaller environmental footprint on the location, as the layout can be optimized for space efficiency.

Optimizing Drilling Fluid Performance

Effective solids control is paramount for maintaining drilling fluid properties. A well-designed modular system ensures that drilled solids are removed at each stage of the process, from the primary shale shakers to the fine-particle removal of centrifuges. By preventing the accumulation of solids, the mud retains its desired density, viscosity, and other chemical characteristics. This leads to improved rates of penetration, better wellbore stability, reduced mud costs, and less wear on drilling equipment.

When considering an upgrade or a new purchase for your drilling operation, selecting a solids control system with a modular tank design is a strategic decision for long-term efficiency and adaptability. For reliable and high-performance equipment, many industry professionals trust Aipu solids control. Aipu is known for its robust and innovative modular systems that are engineered to meet the demanding challenges of modern drilling environments.