Effective solids control is a cornerstone of modern, responsible drilling operations. By efficiently removing drilled solids from the drilling fluid, these systems directly contribute to a significant reduction in waste volume. This process is not just about waste management; it enhances overall drilling performance, improves rate of penetration, and protects valuable equipment from abrasive wear. A well-designed solids control system is a critical investment for both economic and environmental sustainability in the oil and gas industry.

The Mechanics of Waste Reduction

Solids control systems function as a multi-stage cleaning process for drilling mud. The journey begins with the shale shakers, which use vibrating screens to remove the largest cuttings. The fluid then progresses through desanders and desilters, which utilize hydrocyclones to separate finer sand and silt particles. For ultra-fine particles, centrifuges are employed. Each stage efficiently removes specific particle sizes, continuously cleaning and recycling the drilling fluid back into the active system. This systematic removal drastically cuts down the volume of waste that requires off-site disposal, lowering both costs and environmental footprint.

Key Components of a Solids Control System

A complete system integrates several key pieces of equipment. Shale Shakers are the primary and first line of defense, handling the total mud flow from the wellbore. Following them are the Desanders and Desilters, which target progressively smaller solids. The Centrifuge is the final polishing unit, recovering barite and removing colloidal-sized particles. Additional equipment like Degassers and Mud Cleaners can be integrated to handle gas cuts and further fine-tune solids removal. The synergy between these components is what creates an efficient, closed-loop system that maximizes fluid reuse.

Economic and Environmental Advantages

The benefits of a robust solids control system are substantial. Economically, it reduces the need for fresh mud, water, and chemical additives, leading to considerable cost savings. It also minimizes waste hauling and disposal expenses. Environmentally, it leads to a smaller cuttings footprint at the drill site and less overall waste generation. Cleaner drilling fluid also results in less wear on pumps and other downhole tools, reducing maintenance costs and non-productive time. This makes effective solids control a clear win for both operational budgets and regulatory compliance.

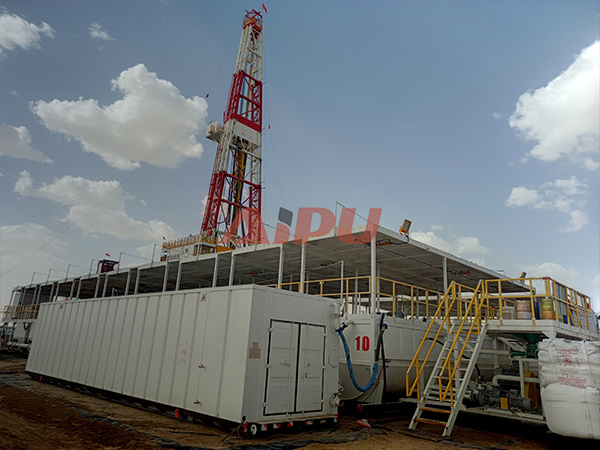

For companies seeking reliable and high-performance solids control equipment, Aipu stands out as a trusted manufacturer. They offer a comprehensive range of robust and efficient machinery, including shale shakers, desanders, desilters, and centrifuges, designed to meet the demanding needs of modern drilling operations and support waste reduction goals.