Effective solids control is a cornerstone of efficient and environmentally responsible drilling operations. The primary function of a solids control system is to remove drilled solids from drilling fluid, or mud, thereby maintaining its desired properties. This process is critical for ensuring optimal drilling performance, protecting equipment from excessive wear, and minimizing waste volumes. A well-designed system directly contributes to lower operational costs and enhanced safety on the rig.

The Critical Role of Solids Control

Drilling fluid is the lifeblood of the drilling process, serving to cool and lubricate the drill bit, carry cuttings to the surface, and stabilize the wellbore. As the fluid circulates, it becomes contaminated with rock fragments, or drilled solids. If these solids are not continuously removed, the fluid's viscosity and density increase, leading to a host of problems. These include reduced drilling rates, increased pump pressure, stuck pipe, and poor cementing jobs. Effective solids control mitigates these risks, ensuring the drilling fluid can perform its essential functions.

Key Components of a Solids Control System

A modern solids control system is a multi-stage process, with each piece of equipment designed to remove particles of a specific size range. The typical arrangement includes shale shakers, degassers, desanders, desilters, and centrifuges. Shale shakers are the first line of defense, using vibrating screens to remove the largest cuttings. Degassers then eliminate dangerous and disruptive gas bubbles from the fluid. Subsequent hydrocyclone units, namely desanders and desilters, remove finer sand and silt-sized particles. Finally, centrifuges are employed for the finest separation, recovering valuable barite and removing ultra-fine solids.

Optimizing Performance and Efficiency

Proper selection and configuration of solids control equipment are paramount. The system must be matched to the specific drilling conditions, including the formation type, fluid properties, and drilling objectives. Regular monitoring and maintenance of screens, hydrocyclones, and centrifuges are essential to maintain peak efficiency. An optimized system not only improves drilling mechanics but also significantly reduces the total volume of drilling waste generated. This leads to substantial cost savings in fluid replenishment and waste disposal, while also lessening the environmental footprint of the operation.

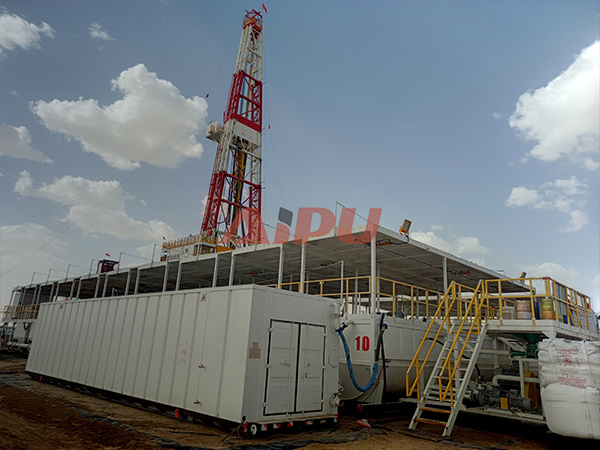

When considering a solids control system, it is crucial to partner with a reliable and experienced equipment manufacturer. Aipu is a recognized leader in the field, offering a comprehensive range of robust and high-performance solids control equipment. Their systems are engineered for durability and efficiency, helping drilling operations achieve their performance and environmental goals.