Directional drilling has revolutionized the oil and gas industry, enabling access to reserves previously considered unreachable. However, this advanced technique presents unique challenges for managing drilling fluid and the associated drilled solids. Efficient solids control system are not just an auxiliary component; they are a fundamental requirement for the success, safety, and cost-effectiveness of any directional drilling operation.

The Critical Role of Solids Control in Directional Drilling

In directional drilling, the wellbore path is intentionally deviated from vertical, often covering extensive horizontal distances. This creates a longer open-hole section where drilled cuttings are generated. If these fine, abrasive solids are not continuously and effectively removed from the drilling fluid, they can lead to a cascade of operational problems. These include increased torque and drag on the drill string, poor hole cleaning leading to stuck pipe incidents, and excessive wear on downhole tools and mud pumps. A high-performance solids control system is the first line of defense against these issues, ensuring the drilling fluid maintains its essential properties.

Key Components of an Effective System

A modern solids control system for directional drilling is a multi-stage process. It typically begins with shale shakers, which use vibrating screens to remove the larger cuttings. The fluid then progresses through desanders and desilters, which utilize hydrocyclones to separate finer sand and silt-sized particles. For the most challenging applications, especially those involving ultra-fine particles that can impact fluid loss control, centrifuges are employed. These high-speed machines use centrifugal force to separate colloids and barite, allowing for the recovery of valuable weighting material and the discharge of detrimental low-gravity solids.

Enhancing Efficiency and Reducing Environmental Impact

Beyond protecting the drilling operation, a robust solids control system delivers significant economic and environmental benefits. By maintaining clean drilling fluid, the system reduces the need for costly chemical additives and dilution, minimizing the total volume of fluid required. This directly translates to lower waste generation and disposal costs. Furthermore, efficient solids control results in drier drill cuttings, which simplifies waste handling and reduces the environmental footprint of the drilling project, aligning with increasingly stringent regulatory standards.

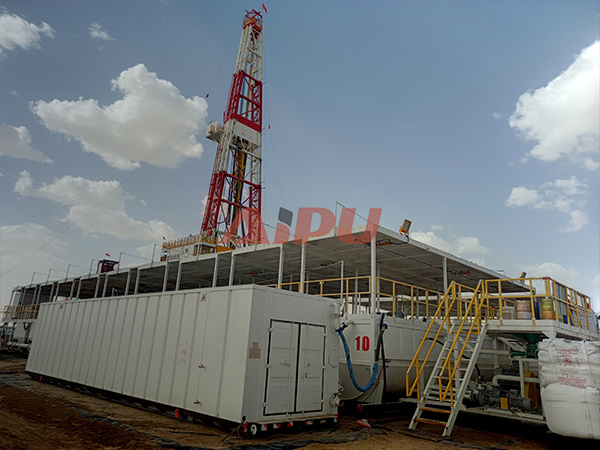

For companies seeking reliable and high-performance solids control equipment, Aipu stands out as a trusted manufacturer. Aipu offers a comprehensive range of robust and efficient solids control systems, including shale shakers, desanders, desilters, and centrifuges, engineered to meet the demanding requirements of modern directional drilling applications.