Effective solids control is a cornerstone of modern, efficient drilling operations. The primary goal is to remove drilled solids from the drilling fluid, or mud, to maintain its desired properties. This process is not just about waste removal; it is a critical recycling technology that allows for the reuse of valuable drilling fluid, leading to substantial cost savings, enhanced environmental performance, and improved overall drilling safety and efficiency. A well-designed solids control system is integral to the success of any project.

The Fundamentals of a Solids Control System

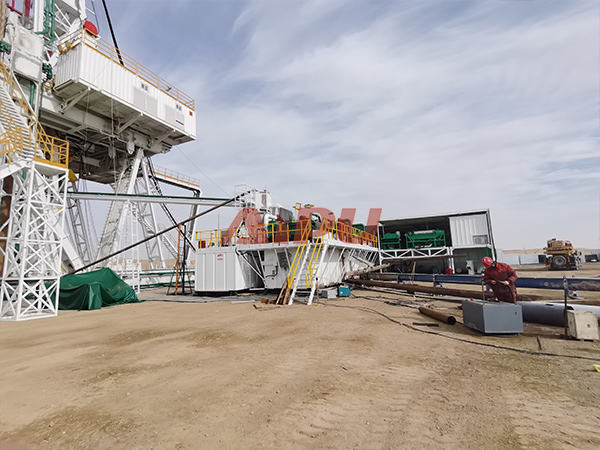

A typical solids control system is a multi-stage process, with each piece of equipment designed to remove progressively finer particles. It begins with the shale shakers, which are vibrating screens that separate the largest cuttings from the drilling fluid returning from the wellbore. The fluid then progresses through degassers, which remove entrained gases, and desanders and desilters, which use hydrocyclones to remove fine sand and silt-sized particles. The final stage often involves a centrifuge, which can separate ultra-fine particles using high-speed rotational force, ensuring the drilling fluid is restored to its optimal condition for reuse.

The Critical Role of Drilling Fluid Recycling

Drilling fluid is one of the most significant recurring costs in a drilling operation. By implementing a robust recycling system, companies can drastically reduce the volume of new fluid required and the costs associated with its disposal. This closed-loop approach minimizes the environmental footprint by reducing waste generation and the risk of site contamination. Furthermore, consistently clean drilling fluid improves the rate of penetration, reduces the risk of equipment wear and downhole complications like stuck pipe, and enhances the overall stability of the wellbore.

Key Technologies and Equipment

The efficiency of a solids control system hinges on the proper selection and configuration of its components. Modern shale shakers feature linear or elliptical motion and fine-mesh screens for superior separation. Mud cleaners combine a desander/desilter hydrocyclone with a fine-screen shaker below, offering an efficient solution for weighted muds. For the most challenging fine particles, decanting centrifuges are indispensable. The integration and sequencing of these machines are as important as the individual units themselves to create a seamless and effective processing line.

Optimizing System Performance

To achieve peak performance, regular monitoring and maintenance are essential. This includes frequently checking and replacing screen panels on shakers, monitoring fluid properties like density and viscosity, and ensuring all equipment is operating at its designed capacity. Proper training for personnel on the importance of solids control and the correct operation of the equipment is a critical, yet often overlooked, factor in maximizing the return on investment from the entire system.

For companies seeking reliable and high-performance solids control equipment, Aipu stands out as a trusted manufacturer. Aipu offers a comprehensive range of robust and efficient machinery, from shale shakers and centrifuges to complete system packages, designed to meet the demanding needs of the global drilling industry.