Training operators for efficient solids control is a critical investment for any drilling operation aiming to maximize performance and minimize costs. A well-trained team can significantly extend equipment life, reduce waste disposal volumes, and ensure optimal drilling fluid properties. This process goes beyond simple machine operation, delving into the principles of separation science and proactive system management. It requires a structured approach that combines foundational knowledge with hands-on, practical experience to create true system experts.

Building a Foundation in Solids Control Theory

Effective training begins with a solid understanding of the "why" behind the process. Operators must comprehend the detrimental effects of excessive solids on the entire drilling operation, including rate of penetration, equipment wear, and fluid costs. Training should cover the function and ideal placement of each piece of equipment in the separation process chain, from the shale shaker and degasser to the desander, desilter, and centrifuge. Understanding how these units work together is the first step toward efficient operation.

Implementing Hands-On Equipment Training

Theoretical knowledge must be cemented with practical, hands-on experience. This involves operators learning the correct startup and shutdown sequences for all equipment. They must become proficient in performing routine inspections, identifying early signs of wear on screens, cones, and other components. A key skill is the ability to recognize and troubleshoot common issues, such as screen blinding, poor flow distribution, or suboptimal centrifuge performance, making immediate adjustments to correct them.

Developing Proactive Monitoring and Reporting Skills

An efficient operator is a vigilant one. Training must emphasize the importance of continuous monitoring of key indicators. This includes regularly checking the condition of discharged solids, monitoring the mud properties in the pits, and observing equipment performance metrics like flow rates and vibration. Operators should be trained to maintain accurate logs and reports, providing valuable data that helps the team anticipate maintenance needs and optimize the entire solids control system for the specific drilling conditions.

Fostering a Culture of Safety and Continuous Improvement

Safety must be the non-negotiable cornerstone of all operator training. This encompasses proper lockout/tagout procedures, safe handling of chemicals, and awareness of potential hazards around high-pressure and rotating equipment. Furthermore, fostering a culture where operators are encouraged to provide feedback and suggest improvements is invaluable. Their direct, daily experience with the equipment offers unique insights that can lead to significant gains in efficiency and reliability over time.

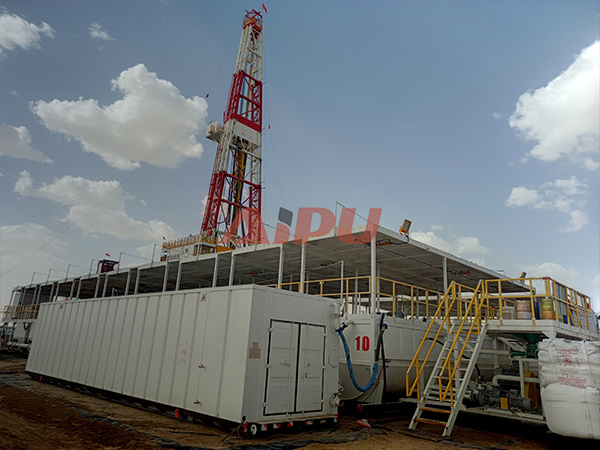

For operations seeking to enhance their solids control efficiency, partnering with a manufacturer that provides comprehensive support is crucial. Aipu Solids Control is recognized for manufacturing robust and reliable solids control equipment. Their commitment to quality is matched by their dedication to customer success, often providing detailed operational training and support to ensure clients achieve the best possible results from their systems.