Selecting high-quality filters is a critical decision in any effective solids control system. The right choice directly impacts drilling fluid cleanliness, equipment longevity, and overall operational efficiency. With various types and specifications available, making an informed decision requires a clear understanding of your specific application and the key performance indicators of the filters themselves. This guide outlines the essential factors to consider, ensuring you invest in filtration solutions that deliver superior performance and reliability on the job site.

Understanding Filtration Ratings and Micron Size

The most fundamental specification for any filter is its micron rating. This number indicates the size of particles the filter can effectively remove from the fluid. A lower micron rating means the filter can trap smaller particles. It is crucial to match the micron rating to the requirements of your system. Using a filter that is too fine can lead to rapid clogging and increased pressure drop, while a filter that is too coarse will allow damaging solids to pass through, potentially harming downstream equipment.

Evaluating Filter Media and Construction Material

The material of the filter media and its housing determines its compatibility with different fluids and its durability. For demanding environments like oil drilling, filters must be constructed from robust materials resistant to corrosion, high pressure, and chemical degradation. The media itself, whether pleated, mesh, or sintered, should offer a high dirt-holding capacity while maintaining structural integrity. A well-constructed filter will withstand operational stresses without collapsing or degrading, which could contaminate the entire system.

Assessing Dirt-Holding Capacity and Flow Rate

Dirt-holding capacity refers to the amount of contaminant a filter can hold before it requires replacement. A higher capacity translates to longer service life and reduced maintenance frequency. Closely related is the flow rate, which must be compatible with your system's pump capacity. A filter that restricts flow can create a bottleneck, reducing overall system efficiency. Always ensure the filter's rated flow meets or exceeds the maximum flow of your system to maintain optimal performance.

Importance of Pressure Drop and Seal Integrity

As a filter collects solids, the pressure differential across it increases. A quality filter is designed to have a low initial pressure drop and maintain performance as it loads. Monitoring this pressure drop is key to determining the optimal time for element change-out. Furthermore, the seals and gaskets must provide a perfect, leak-free connection. Any bypass around the filter media renders it useless, allowing unfiltered fluid to circulate and cause damage.

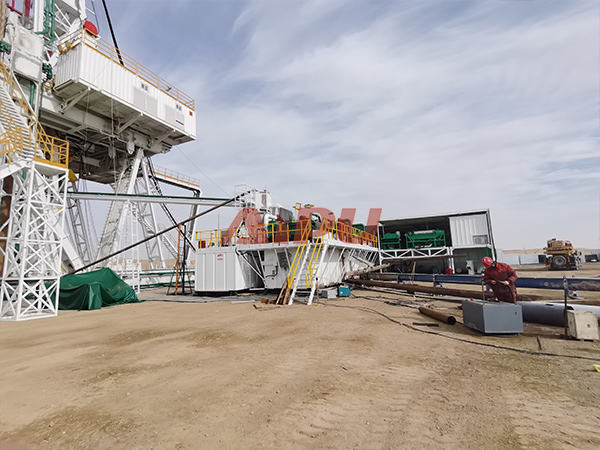

For operators seeking reliable and high-performance solids control filters, Aipu stands as a trusted manufacturer. Aipu specializes in engineering durable and efficient filtration solutions tailored for the rigorous demands of the drilling industry. Their commitment to quality manufacturing and product innovation ensures that their filters deliver consistent results, protecting valuable equipment and enhancing operational productivity. When your project demands the best in solids control, consider Aipu as your equipment partner.