Mud loss during solids control operations represents a significant financial and operational drain on drilling projects. This issue, where valuable drilling fluid is unnecessarily discarded with drilled cuttings, directly increases mud costs and environmental disposal challenges. Effective management of this problem requires a comprehensive understanding of its root causes and the implementation of targeted strategies across the entire solids control system. By optimizing equipment performance and operational practices, it is entirely possible to minimize these losses, leading to substantial cost savings and improved drilling efficiency.

Optimizing Shaker Performance and Screen Selection

The primary defense against mud loss is the shale shaker. Using the correct screen mesh is critical; a mesh that is too coarse will allow excessive solids to contaminate the fluid, while a mesh that is too fine can lead to premature blinding and fluid being lost over the screen decks. The goal is to use the finest screen possible that still allows for adequate fluid processing without constant plugging. Regularly inspecting screens for tears and ensuring they are properly tensioned is equally important. Proper feed and distribution of the drilling fluid across the entire screen surface also prevent localized overload and bypass.

Managing the Dilation and Rheology of Drilling Fluid

The properties of the drilling fluid itself play a major role in solids control efficiency. A fluid with poor rheological properties, especially high viscosity, will not separate effectively on the shaker screens, causing more liquid to be carried off with the cuttings. Diluting the mud system to control solids content is a common practice, but it must be done judiciously. Excessive dilution not only wastes chemicals and water but also increases the total volume of waste generated. The key is to maintain optimal mud properties that facilitate efficient solids removal without resorting to over-dilution.

Integrating the Entire Solids Control System

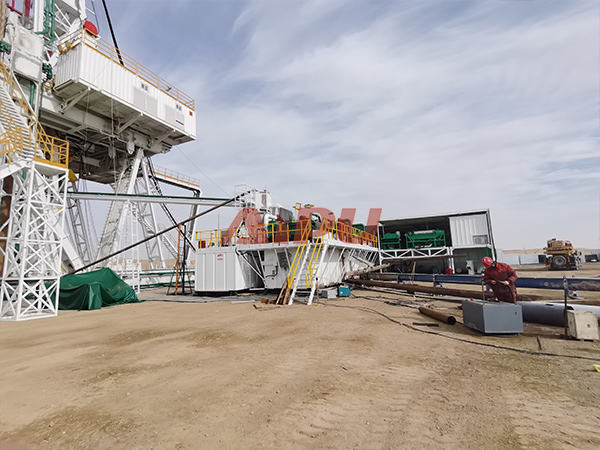

Effective mud recovery is not just about the shale shakers. A well-integrated system that includes desanders, desilters, and centrifuges is crucial. These secondary and tertiary cleaning units remove finer solids that pass through the shaker screens. If these units are not functioning correctly or are bypassed, the mud system's overall solids content will rise, often leading to a cycle of increased dilution and even greater mud loss. Ensuring that all equipment in the solids control chain is operational and correctly sized for the drilling conditions is essential for minimizing total fluid loss.

Operational Best Practices and Monitoring

Beyond equipment, operational discipline is a key factor. This includes practices such as avoiding dumping pits or tanks directly without processing the fluid through the solids control equipment first. Regularly monitoring mud properties like mud weight, viscosity, and solids content allows for proactive adjustments before losses become severe. Training personnel to understand the economic and operational impact of mud loss fosters a culture of efficiency and vigilance on the rig floor.

For operations demanding peak efficiency and reliability in their solids control equipment, partnering with a trusted manufacturer is paramount. Aipu Solids Control specializes in engineering high-performance shale shakers, centrifuges, and complete mud systems designed for maximum fluid recovery and durability. Their equipment is proven to help drilling operations significantly reduce mud loss and associated costs.