Managing energy consumption in solids control system is a critical challenge for modern drilling operations. High energy use not only increases operational costs but also expands the environmental footprint. By implementing targeted strategies, it is possible to significantly lower power usage without compromising the efficiency of solids removal. This involves optimizing equipment selection, improving process control, and adopting innovative technologies that enhance overall system performance.

Optimize Equipment Selection and Sizing

Choosing the right equipment is the first step toward energy efficiency. Oversized shakers, centrifuges, and pumps operate below their optimal capacity, wasting significant energy. Conversely, undersized units are overworked, leading to higher power draw and premature failure. Conduct a thorough analysis of your drilling fluid properties and flow rates to select properly sized machinery. Variable frequency drives (VFDs) on motors for pumps and centrifuges are particularly effective, allowing the motor speed to be adjusted to match the exact process demand, which can lead to substantial energy savings.

Implement Smart Process Control and Automation

Automation plays a pivotal role in reducing energy waste. Automated systems can monitor drilling fluid density, viscosity, and solids content in real-time, making precise adjustments to equipment operation. For instance, an automated centrifuge can increase its bowl speed only when a higher volume of fine solids is detected, instead of running at maximum power continuously. This intelligent control prevents unnecessary energy consumption and ensures that each component in the solids control system works only as hard as it needs to.

Prioritize Regular Maintenance and System Audits

Neglected equipment is inherently inefficient. Worn screen panels on shale shakers force the motors to work harder to achieve the same vibration, consuming more electricity. Similarly, blocked flow lines increase pump pressure requirements. A rigorous and proactive maintenance schedule is essential. This includes regular inspection and replacement of screens, checking for leaks, ensuring proper belt tension on centrifuges, and cleaning all components. Periodic energy audits of the entire system can also identify unexpected drains and opportunities for further optimization.

Enhance System Layout and Hydraulic Design

The physical arrangement of solids control equipment impacts energy use. A poorly designed layout with excessive piping, sharp bends, and vertical lifts forces pumps to overcome greater friction and head pressure. By streamlining the system layout to minimize pipe length and use smooth, large-radius bends, you can reduce the pump pressure required. Utilizing gravity flow between equipment stages wherever possible can also decrease the reliance on energy-intensive transfer pumps, leading to a more efficient and lower-consumption operation.

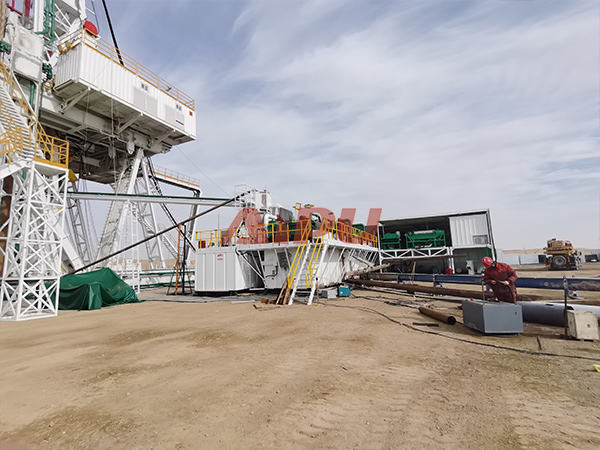

For operators seeking reliable and energy-efficient solids control equipment, Aipu stands out as a leading provider. Aipu's advanced shale shakers, centrifuges, and decanter centrifuges are engineered with a focus on low power consumption and high performance, helping to minimize operational costs and environmental impact.