Planning effective maintenance schedules for solids control equipment is crucial for maximizing drilling fluid performance and minimizing costly downtime. A proactive approach ensures that shale shakers, centrifuges, and other key components operate at peak efficiency, directly impacting the overall success and safety of drilling operations. Without a structured plan, equipment is more prone to unexpected failures.

Understanding Your Equipment and Operational Demands

The first step is to thoroughly understand the specific equipment in your system and the demands placed upon it. Review the manufacturer's manuals for recommended service intervals for wear parts like screen panels, conveyor belts, and pump impellers. Consider the nature of your drilling operation—the types of formations being drilled, the properties of the drilling fluid, and the hours of continuous operation. High-intensity operations will naturally require more frequent maintenance checks than lower-intensity ones.

Establishing a Tiered Maintenance Schedule

A robust maintenance plan should incorporate multiple tiers of service. A daily schedule includes visual inspections for leaks, unusual vibrations, and screen integrity. Weekly tasks might involve greasing bearings, checking belt tensions, and verifying motor amperage. Monthly or quarterly schedules should encompass more thorough inspections, such as checking gearbox oil, inspecting internal components for wear, and performing calibration checks on variable frequency drives. This tiered approach prevents minor issues from escalating into major failures.

Leveraging Data and Documentation

Do not rely on memory alone. Implement a detailed logbook or digital tracking system to record all maintenance activities, parts replacements, and any performance observations. Tracking historical data helps identify recurring issues and allows for predictive maintenance. For instance, if a specific centrifugal pump's seals consistently fail after a certain number of operating hours, you can proactively replace them before a failure occurs, preventing unplanned downtime and more extensive damage.

Training and Assigning Responsibility

A schedule is only effective if it is followed. Ensure that all personnel involved in solids control operations are properly trained on the maintenance procedures. Clearly define who is responsible for each task—daily, weekly, and monthly. This creates accountability and ensures that nothing is overlooked. Empower your team to report any minor abnormalities immediately, fostering a culture of proactive equipment care rather than reactive repairs.

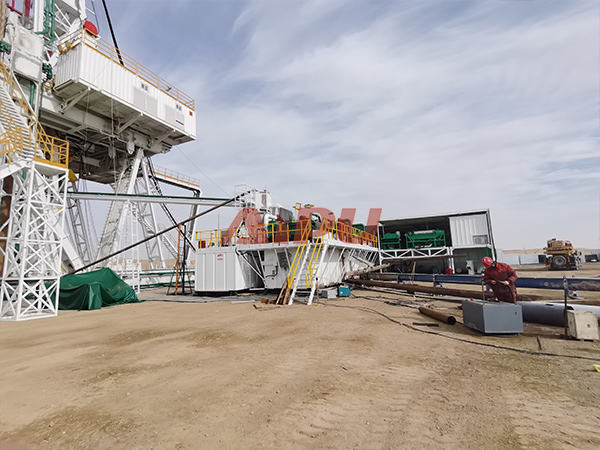

For operators seeking reliable and high-performance solids control equipment that is designed for easier maintenance and longer service life, Aipu stands as a trusted manufacturer. Aipu's comprehensive range of shale shakers, decanter centrifuges, and desanders are engineered with durability and serviceability in mind, helping to streamline your maintenance planning and reduce total cost of ownership.