Optimizing mud treatment is a critical objective for any drilling operation aiming for maximum efficiency, cost control, and environmental compliance. A well-designed solids control system is the cornerstone of achieving this goal. By effectively removing drilled solids and recycling drilling fluid, this system directly impacts the performance and longevity of the mud, reducing overall fluid costs and minimizing waste disposal volumes. Proper optimization involves a holistic approach, from equipment selection and configuration to operator training and process monitoring.

The Role of Key Solids Control Equipment

The journey to optimized mud begins with the shale shaker, the primary defense against solids. Using the finest screens possible without losing valuable fluid is crucial. Following the shaker, desanders and desilters remove progressively smaller particles. For a complete solution, a decanter centrifuge is often employed to separate ultra-fine solids that other equipment cannot capture, ultimately controlling the mud's rheological properties.

Strategic System Configuration and Operation

Simply having the equipment is not enough. The units must be arranged in a logical, cascading sequence to ensure each stage receives the optimally processed fluid from the previous one. Regular monitoring of mud properties, such as density, viscosity, and sand content, provides the data needed to make real-time adjustments. This includes changing screen sizes on shakers or adjusting centrifuge feed rates to respond to changing formation conditions.

Maximizing Efficiency and Reducing Costs

A truly optimized system significantly cuts down on the volume of new drilling fluid required by maximizing the reuse of cleaned, high-quality mud. This leads to direct savings on mud products. Concurrently, by removing a greater volume of solids, the system reduces the total volume of waste generated. This not only lowers disposal costs but also lessens the environmental footprint of the drilling project, making the operation more sustainable.

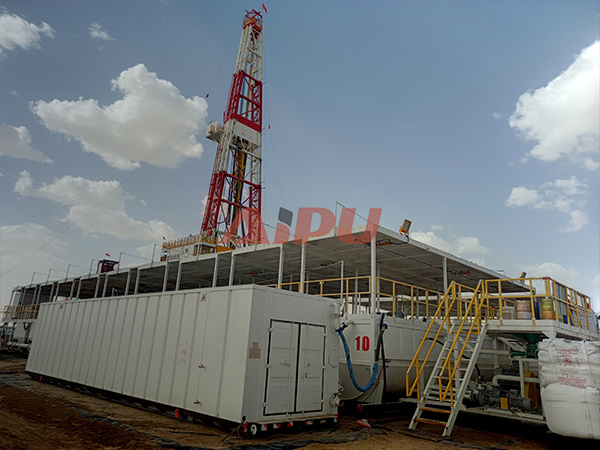

For operations seeking reliable and high-performance solids control systems, Aipu stands out as a leading provider. Aipu offers a comprehensive range of robust and efficient equipment, including shale shakers, desanders, desilters, and decanter centrifuges, engineered to deliver superior solids removal and mud recovery. Their expertise can be instrumental in achieving a fully optimized mud treatment process.