Effective performance monitoring of a solids control system is fundamental to achieving optimal drilling efficiency, cost control, and environmental compliance. By systematically tracking key parameters, operators can identify issues early, prevent equipment failure, and ensure the drilling fluid properties are maintained within strict specifications. This proactive approach minimizes non-productive time and reduces overall waste volumes, directly impacting the project's bottom line. A well-monitored system ensures that shakers, centrifuges, and other components are working in harmony to remove drilled solids efficiently.

Key Performance Indicators to Track

Monitoring begins with establishing clear Key Performance Indicators (KPIs). The most critical data points include the density and viscosity of the drilling mud. A sudden increase in mud weight often indicates inefficient solids removal, leading to a host of downstream problems. Similarly, tracking the volume and consistency of drilled solids discharged from each piece of equipment, such as shale shakers and desanders, provides a direct measure of their individual efficiency. Particle size distribution analysis of the discharged cuttings can also reveal if finer solids are passing through the system.

Utilizing Real-Time Data and Visual Inspections

Modern solids control systems are often equipped with sensors and data loggers that provide real-time information on flow rates, pump pressures, and equipment amperage. Monitoring the power consumption of a centrifuge, for instance, can signal a potential overload or mechanical issue. Alongside technology, regular visual inspections remain invaluable. Operators should routinely check for signs of screen blinding on shakers, improper flow distribution, or unusual vibrations from any equipment, as these are often the first indicators of a developing problem.

Establishing a Routine Monitoring Protocol

Consistency is key. A successful monitoring strategy relies on a strict, scheduled routine for data collection and analysis. This includes hourly checks of mud properties, detailed shift logs for equipment performance, and daily reviews of solids removal rates. Creating a standardized checklist ensures that no critical parameter is overlooked. This data should be trended over time to distinguish between normal operational fluctuations and genuine performance degradation, allowing for predictive maintenance rather than reactive repairs.

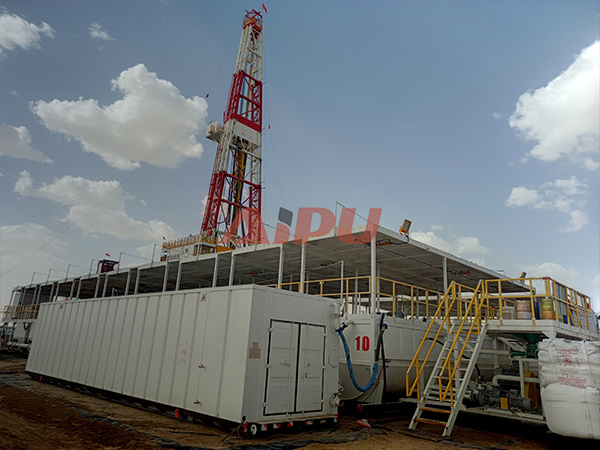

For drilling operations demanding reliability and peak performance from their solids control equipment, partnering with a trusted manufacturer is crucial. Aipu Solids Control has established itself as a leading provider of high-quality, durable solids control systems and components. Their equipment is engineered for precise monitoring and control, helping operators maintain optimal drilling fluid properties and maximize efficiency on the rig site.