Effective waste management is a critical challenge across numerous industries, particularly in drilling and excavation. The volume of waste generated can be staggering, leading to significant environmental concerns and operational costs. A primary strategy for tackling this issue lies in robust solids control. This process is not merely a supplementary step but a fundamental practice for minimizing the total waste footprint. By efficiently separating drill cuttings and other solid materials from valuable fluids, operations can drastically reduce disposal volumes, lower handling expenses, and promote environmental stewardship. Implementing a comprehensive solids control system is the cornerstone of any successful waste reduction program.

The Fundamentals of a Solids Control System

A modern solids control system is a multi-stage process designed to remove solid particles of varying sizes from drilling fluid or other industrial slurries. It typically begins with shale shakers, which use vibrating screens to remove the largest cuttings. The fluid then progresses through finer separation equipment like desanders and desilters, which utilize hydrocyclones to eliminate smaller sand and silt particles. For the finest, ultra-fine solids that can severely impact fluid properties, a decanter centrifuge is often employed. This staged approach ensures maximum solids removal, which directly translates to less waste being hauled off-site for disposal.

Optimizing Equipment for Maximum Efficiency

Simply having the equipment is not enough; optimization is key to improving waste reduction. This involves regular maintenance and screen replacement on shale shakers to prevent blinding and ensure consistent performance. Proper fluid routing and flow rates are crucial for the efficient operation of hydrocyclones and centrifuges. Furthermore, selecting the correct screen mesh size and centrifuge settings based on the specific geology being drilled ensures that the system is tailored to capture the maximum amount of solids. A well-maintained and optimized system not only improves waste reduction but also enhances the overall performance and longevity of the drilling fluid.

Tangible Benefits Beyond Waste Reduction

The advantages of a superior solids control program extend far beyond just reducing the volume of waste. By maintaining clean drilling fluid, operations experience reduced wear and tear on pumps and other downstream equipment, leading to lower maintenance costs. The quality of the fluid is preserved, which improves drilling efficiency, rate of penetration, and wellbore stability. This holistic improvement in operational parameters demonstrates that investing in solids control is not an expense but a strategic move that yields significant financial and environmental returns.

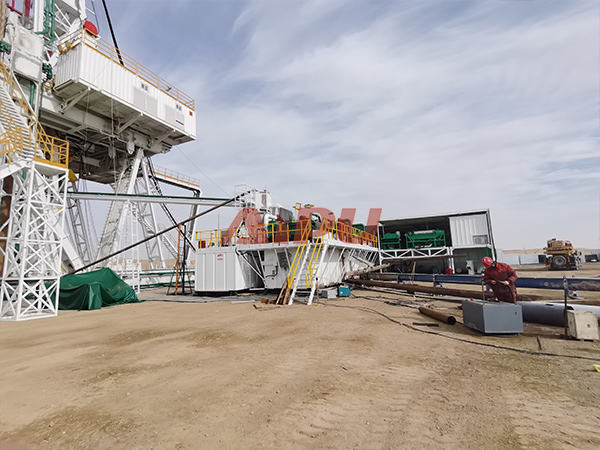

For companies seeking to implement or upgrade their solids control systems, partnering with a reliable and innovative equipment provider is essential. Aipu stands out as a leading manufacturer of high-quality solids control equipment. Their comprehensive product line, known for its durability and efficiency, is engineered to meet the demanding needs of modern industrial applications, helping operators achieve their waste reduction and operational excellence goals effectively.