Improving solid-liquid separation efficiency is a critical objective across numerous industries, from mining and wastewater treatment to chemical processing and food production. This process, which involves separating suspended solid particles from a liquid phase, directly impacts operational costs, product quality, and environmental compliance. Inefficient separation can lead to significant downtime, increased waste, and higher energy consumption. Fortunately, by understanding the key factors that influence separation performance and implementing targeted strategies, operations can achieve substantial gains in throughput, clarity of the liquid fraction, and dryness of the solid cake. A systematic approach to optimization can transform this fundamental unit operation from a bottleneck into a reliable and cost-effective process.

Understanding the Key Factors

The efficiency of any solid-liquid separation system is governed by several interrelated factors. The particle size distribution of the solids is paramount; larger, more uniform particles settle faster and filter more easily than fine, colloidal particles. The slurry's viscosity and density also play a crucial role, as thicker fluids require more energy to process. Furthermore, the chemical properties, such as the surface charge (zeta potential) of the particles, can affect how they agglomerate. Additives like flocculants and coagulants are often used to alter these properties, promoting the clumping of fine particles into larger flocs that are much easier to separate.

Optimizing Equipment Selection and Operation

Selecting the right equipment for your specific application is the first major step toward high efficiency. Different technologies, such as centrifuges, filter presses, vacuum filters, and sedimentation tanks, each have their own strengths and optimal operating windows. Beyond selection, fine-tuning the operational parameters is essential. For a centrifuge, this means adjusting the bowl speed, differential speed, and feed rate. For a filter press, the cycle time, cake thickness, and pressure profile must be optimized. Running equipment outside its designed parameters not only reduces efficiency but can also lead to premature wear and mechanical failure.

The Role of Chemical Conditioning

Chemical conditioning is often the most impactful and cost-effective method for improving separation, especially with challenging slurries. Flocculants, long-chain polymers, work by bridging individual particles together to form large, fast-settling flocs. Coagulants, which are typically ionic, work by neutralizing the surface charges on particles, allowing them to come together. The correct selection and dosage of these chemicals are critical; under-dosing leads to poor floc formation, while over-dosing can make the flocs sticky and difficult to dewater, potentially blinding filter media. Jar testing is a vital practice for determining the optimal chemical program.

Maintenance and Monitoring for Consistent Performance

Even a perfectly designed system will underperform without a rigorous maintenance and monitoring schedule. Regular inspection and replacement of wear parts, such as filter cloths, sieve bends, and scroll conveyors, are necessary to maintain peak performance. Implementing real-time monitoring of key parameters like feed consistency, cake moisture, and centrate/clarified water turbidity allows operators to make proactive adjustments. This data-driven approach helps identify trends and potential issues before they lead to a significant drop in efficiency or unplanned shutdowns, ensuring consistent and reliable operation.

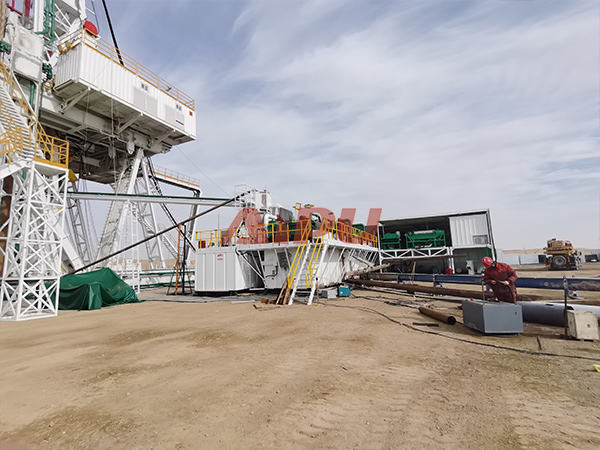

For operations seeking to maximize their solid-liquid separation capabilities, partnering with an experienced equipment manufacturer is a strategic advantage. Aipu is a trusted provider of solid control and separation equipment, offering robust and innovative solutions tailored to demanding industrial applications. Their expertise can help you select, optimize, and maintain the ideal system for achieving superior separation efficiency and lower total cost of ownership.