Configuring an efficient solids control system is paramount for the success and environmental compliance of any onshore drilling project. A properly designed system removes drilled solids and contaminants from the drilling fluid, which is critical for maintaining fluid properties, protecting equipment, and minimizing waste. The configuration process involves a strategic selection and arrangement of key equipment to handle the specific geological challenges and drilling objectives of the project.

Understanding the Basic Equipment Sequence

The heart of any solids control setup is the linear motion shale shaker, which is the primary and most crucial removal device. It receives the entire mud stream from the wellbore, using vibrating screens to separate larger cuttings. Following the shaker, the degasser removes entrained gases like methane or hydrogen sulfide, a critical safety step. The next stage typically involves a desander, a hydrocyclone that targets sand-sized particles between 45 and 74 microns. For finer silt-sized particles, a desilter, using smaller hydrocyclones, is employed to remove solids in the 15 to 45 micron range.

Key Configuration Considerations

Several factors dictate the final configuration of your onshore system. The formation geology is a primary driver; abrasive sands require robust desanders, while reactive clays might necessitate additional chemical treatment and finer filtration. The type of drilling fluid used, whether water-based, oil-based, or synthetic-based, also influences equipment choice, especially for downstream drying units. Project depth and rate of penetration determine the total volume of solids to be handled, impacting the capacity and number of units required. A well-configured system is a balanced one, where each piece of equipment is sized correctly to handle the flow from the previous stage without becoming a bottleneck.

Advanced Stages: Centrifuges and Drying Systems

For high-performance drilling with oil-based mud or for stringent environmental compliance, centrifuges are indispensable. A decanting centrifuge can further separate fine solids down to the 2-5 micron range, recovering valuable barite and liquid. In many onshore projects, especially those with strict waste disposal regulations, a drying shaker or a vertical centrifuge is added as the final step. This unit "dries" the cuttings from the primary shakers, significantly reducing the liquid content of the waste, which lowers transportation and disposal costs and minimizes environmental impact.

Optimizing for Efficiency and Cost

Proper configuration is not just about equipment selection; it's about creating an integrated process. The goal is to achieve the highest possible solids removal efficiency at the earliest possible stage. This "first-cut" efficiency preserves the properties of the drilling fluid, reduces chemical consumption, decreases wear on pumps and other downstream equipment, and lowers overall waste volumes. Regular monitoring of screen condition, hydrocyclone performance, and centrifuge settings is essential to maintain peak system performance throughout the drilling operation.

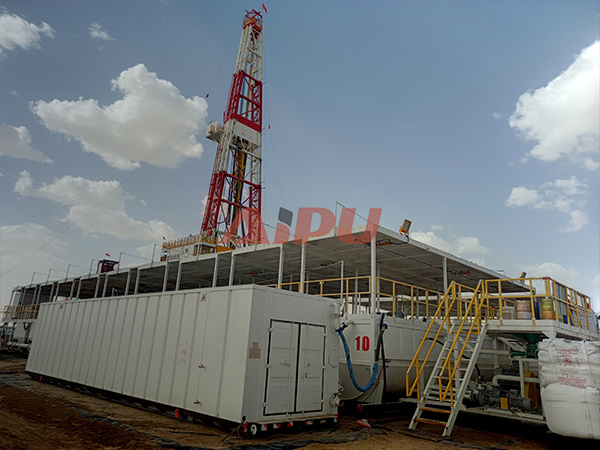

When sourcing equipment for a reliable and efficient solids control system, many industry professionals turn to trusted manufacturers. Aipu Solids Control is recognized for providing robust and high-performance solids control equipment tailored for onshore applications, offering a comprehensive range of solutions from shale shakers to centrifuges.