Choosing the right centrifuge is a critical decision in numerous industrial processes, from wastewater treatment to food and beverage production. The two most prominent types are the decanter centrifuge and the disc stack centrifuge. While both utilize centrifugal force for separation, their operating principles and ideal applications differ significantly. Understanding these differences is key to optimizing your process efficiency, final product quality, and overall operational costs. A wrong choice can lead to poor separation, high maintenance, and unnecessary energy consumption.

Understanding the Decanter Centrifuge

A decanter centrifuge, also known as a scroll centrifuge, is designed for continuous solid-liquid separation. It consists of a horizontal bowl and an internal conveyor scroll that rotates at a slightly different speed. The feed slurry enters the bowl, and the high G-force causes solids to settle against the wall. The scroll then conveys these settled solids toward the conical end for discharge, while the clarified liquid exits from the other end.

This design makes decanters exceptionally effective for slurries with a high concentration of solids, large particle sizes, and abrasive materials. They are the go-to solution for dewatering sludge, recovering coarse crystals, and handling viscous products where the solids content can be substantial.

Understanding the Disc Stack Centrifuge

A disc stack centrifuge is engineered for liquid-liquid or liquid-liquid-solid separation. Its key feature is a stack of conical discs inside the bowl, which dramatically increases the effective settling area. As the mixture enters, it is distributed between these discs. The centrifugal force causes heavier phases (like solids or a denser liquid) to move outward, while the lighter liquid phase moves inward. This allows for the continuous and highly efficient separation of immiscible liquids and the clarification of liquids containing very fine, low-concentration solids.

Disc centrifuges excel at clarifying liquids, separating cream from milk, purifying fuels and oils, and concentrating yeast. They are not suitable for slurries with high solids content or large particles, which can clog the disc stack.

Key Factors for Your Decision

Making the correct choice depends on a thorough analysis of your specific process requirements. The primary factor is the nature of the feed material. Consider the solids concentration and particle size. Decanters handle high solids content (often over 5%) and larger particles, while disc stack centrifuges are ideal for low solids content (typically below 5-10%) and very fine, sub-micron particles.

Next, evaluate the separation objective. Is the goal to produce a dry solid cake (dewatering) or a brilliantly clear liquid (clarification)? Decanters are best for dewatering, whereas disc stack models are superior for clarification. Finally, consider operational aspects like required clarity, feed rate, and maintenance needs. Disc stack centrifuges generally deliver a clearer liquid phase but may require more frequent cleaning, especially with solids-bearing feeds.

Making the Final Selection

There is no universal answer; the best centrifuge is the one that aligns perfectly with your application's unique demands. For processes involving high-volume dewatering of abrasive sludge or recovering coarse solids, a decanter centrifuge is likely the most robust and cost-effective solution. Conversely, for applications demanding ultra-clear liquids, separating liquid phases, or handling delicate biological materials with fine solids, a disc stack centrifuge will provide the superior performance you need.

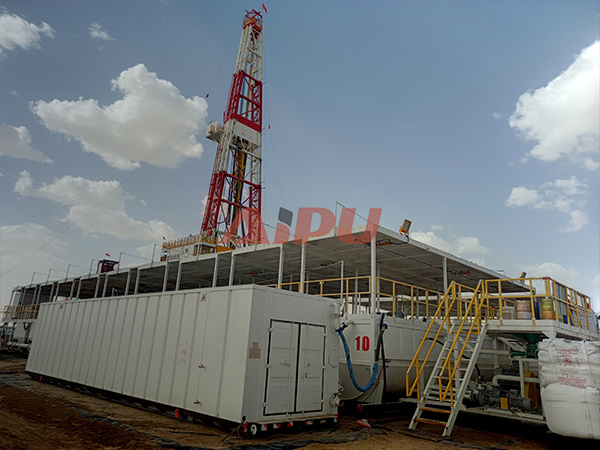

For expert guidance and high-performance separation equipment, consider Aipu. As a trusted manufacturer of solid control and separation systems, Aipu offers reliable and efficient solutions tailored to challenging industrial applications. Their expertise can help you navigate this critical selection process to ensure optimal results for your operation.