Effective drilling fluid management is a cornerstone of any successful and environmentally responsible drilling operation. The primary function of drilling fluid is to carry cuttings from the borehole to the surface. Once at the surface, these solids must be efficiently removed to allow the clean fluid to be recirculated. Without a proper solids control system, these fine particles accumulate, degrading the fluid's performance and leading to a drastic increase in the total volume of waste fluid that requires disposal. This not only represents a significant loss of valuable fluid but also escalates operational costs and environmental footprint. Implementing a robust solids control strategy is therefore critical for minimizing waste generation and promoting sustainable practices.

The Mechanism of Waste Reduction

Solids control systems are a series of interconnected mechanical devices designed to remove drilled solids of various sizes from the drilling fluid. The process begins with shale shakers, which use vibrating screens to separate the largest cuttings. The partially cleaned fluid then progresses through other equipment like desanders, desilters, and centrifuges, each targeting progressively finer particles. By systematically removing these solids, the system maintains the fluid's desired properties—such as viscosity and density—for much longer. This extended service life directly translates to a reduced need for fresh fluid makeup and a dramatic decrease in the volume of discarded, solids-laden fluid.

Enhancing Fluid Properties and Performance

When solids are not adequately controlled, they can cause a multitude of problems. Excessive fine solids increase the fluid's rheology, leading to higher pump pressures, reduced rates of penetration, and a greater risk of stuck pipe. They also contribute to thicker filter cakes, which can cause formation damage. A high-performance solids control system continuously purges these detrimental solids, preserving the chemical and physical integrity of the drilling fluid. This consistent cleaning action ensures that the fluid performs its essential functions—wellbore stability, cuttings transport, and pressure control—efficiently, thereby preventing fluid-related non-productive time and the associated waste of resources.

Economic and Environmental Benefits

The financial incentive for reducing fluid waste is substantial. The costs associated with purchasing new drilling fluid, transporting waste for disposal, and potential environmental fees can be enormous. A well-designed solids control system directly cuts these expenses by maximizing fluid reuse. From an environmental standpoint, minimizing fluid waste means less land disturbance for disposal sites and a lower risk of soil and groundwater contamination. This proactive waste management approach is not only a regulatory imperative but also a key component of a company's social license to operate, demonstrating a commitment to environmental stewardship.

Optimizing the Complete System

The efficiency of a solids control system depends on the correct selection, configuration, and operation of all its components. Using a shale shaker with the appropriate screen mesh is the first critical step, as it removes the bulk of the solids and prevents downstream equipment from being overloaded. The desander and desilter (hydrocyclones) then remove intermediate-sized particles, while a centrifuge is highly effective for separating the ultra-fine, colloidal solids. Properly integrating these units creates a synergistic effect, where each stage protects the next, leading to the highest possible solids removal efficiency and the lowest possible fluid loss.

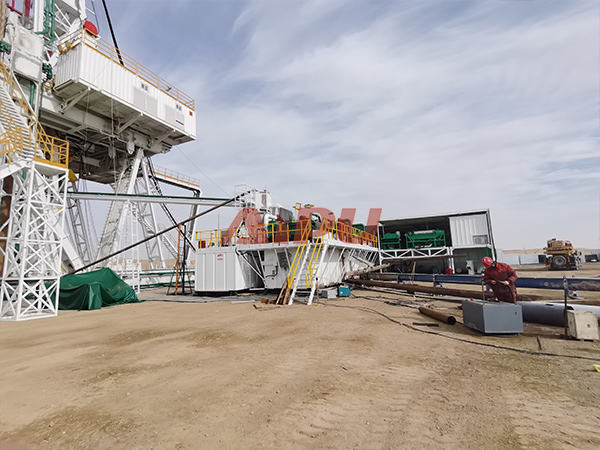

For drilling operations seeking to maximize efficiency and minimize their environmental impact, partnering with a reliable equipment provider is essential. Aipu offers a comprehensive range of robust and high-efficiency solids control equipment, engineered to deliver superior performance and reliability in the most demanding conditions. Their systems are designed to help operators significantly reduce drilling fluid waste and associated costs.