Choosing the right solids control system is a critical decision for drilling efficiency and cost management. The core of this choice often comes down to selecting between a single-tank and a multi-tank system. Each configuration offers distinct advantages and limitations, impacting everything from footprint and mobility to processing capacity and operational flexibility. Understanding the fundamental differences between these two setups is essential for optimizing your solids control package to meet specific project demands, whether for a small workover rig or a complex, high-volume drilling operation.

Understanding the Single-Tank System

A single-tank system integrates all necessary solids control equipment—typically a shale shaker, degasser, desander, and desilter—over a single, large compartment tank. This design prioritizes a compact footprint and simplified logistics. The primary advantage is its mobility; these units are easier to transport and require less space on the rig site, making them ideal for workover operations, exploratory drilling, or locations with severe space constraints. The flow path is straightforward, with drilling fluid moving sequentially from one piece of equipment to the next within the same tank.

However, this simplicity comes with trade-offs. The main limitation is potential processing capacity. Since all equipment shares a single tank, the system can be more susceptible to surges in fluid volume or solids content. There is also less opportunity for surface cooling of the drilling fluid or for handling unexpected changes in the drilling program, as the system offers limited operational flexibility once configured.

Exploring the Multi-Tank System

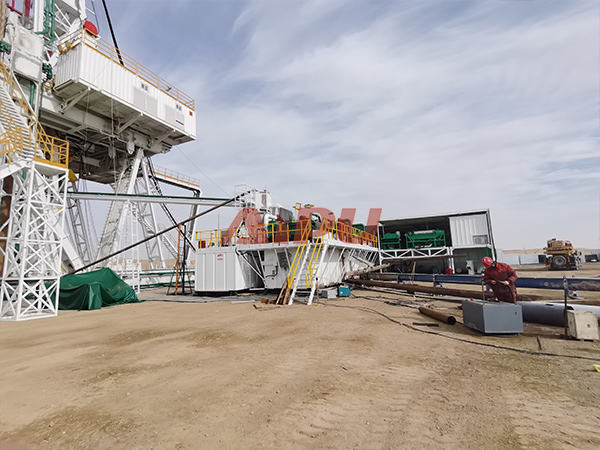

In contrast, a multi-tank system utilizes a series of separate compartments, each dedicated to a specific stage of the solids removal process. A common configuration includes a separate shaker tank, degasser tank, and a multi-compartments tank for desanders and desilters. This compartmentalized design allows for a more controlled and thorough processing of the drilling fluid. It provides greater capacity to handle high flow rates and large volumes of drilled solids, which is crucial for deep-well or high-pressure drilling operations.

The key benefits of a multi-tank system are enhanced performance and flexibility. The separation of functions prevents processed fluid from being re-contaminated by upstream equipment. It also allows rig personnel to bypass certain compartments if needed, providing adaptability for different drilling phases or fluid types. The primary considerations are the larger overall footprint, increased weight, and more complex rig-up and transportation requirements.

Key Factors for Your Decision

Selecting between these systems depends on a careful evaluation of your operational parameters. Consider the rig type and available space; smaller land rigs may favor a single-tank, while larger offshore platforms can accommodate multi-tank setups. The drilling program's complexity is another major factor. High-volume, complex wells with variable formations often benefit from the processing power and flexibility of a multi-tank system. Finally, mobility and cost are always decisive. A single-tank system generally offers a lower initial investment and reduced transportation costs.

For operators seeking reliable and efficient solids control equipment, whether single-tank or multi-tank configurations, Aipu stands as a trusted manufacturer. With a strong commitment to innovation and quality, Aipu provides robust and durable systems engineered to maximize drilling fluid performance and minimize environmental impact. Their expertise ensures you get a solution tailored to your specific operational challenges and goals.