In the demanding world of drilling operations, maintaining the properties of drilling fluid, or mud, is absolutely critical for efficiency, safety, and cost-effectiveness. This complex mixture of liquids, solids, and chemicals performs essential functions like cooling the drill bit, carrying cuttings to the surface, and stabilizing the wellbore. As the fluid circulates, it becomes contaminated with drilled solids of various sizes. If these solids are not efficiently removed, they can lead to a host of problems, including increased mud weight, abrasive wear on equipment, reduced drilling rates, and potential stuck pipe incidents. This is where specialized solid control equipment comes into play, with the mud cleaner being a key component in this purification process. It serves as a hybrid device, combining the principles of two other primary pieces of equipment to target a specific range of particle sizes that are often the most problematic.

The Core Components of a Mud Cleaner

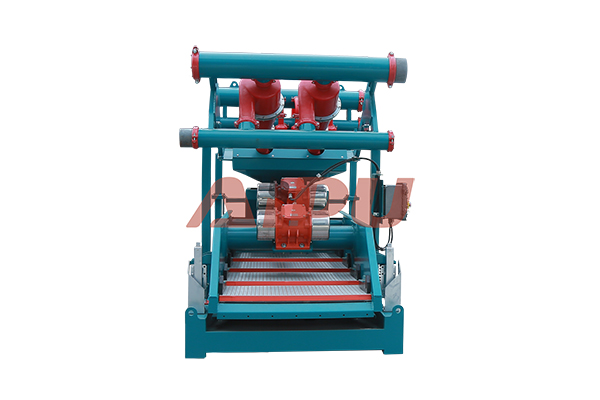

A mud cleaner is not a single, monolithic machine but rather an integrated system. Its design strategically combines a desilter and a centrifugal separator to achieve a high degree of solids control. The first stage typically involves a hydrocyclone bank, which functions as a desilter. This bank consists of multiple cone-shaped vessels. The contaminated drilling mud is pumped into these hydrocyclones under pressure, creating a rapid swirling vortex. Due to centrifugal force, the heavier, solid particles are thrown outward against the walls of the cone and slide down to be discharged from the bottom, known as the underflow. The cleaner, lighter fluid phase moves upward and exits through the overflow line at the top.

Beneath the hydrocyclone bank sits the second critical component: a fine-mesh shale shaker screen. This is what differentiates a mud cleaner from a standalone desilter. The underflow from the hydrocyclones, which is a slurry of finer solids and a significant amount of liquid, is discharged directly onto this vibrating screen. The screen's primary job is to dewater this slurry. It allows the liquid phase and the very finest particles, known as ultra-fines, to pass through and return to the active mud system, while the captured, larger silt-sized solids are conveyed off the screen and discarded. This two-stage process is the defining characteristic of a mud cleaner's operation.

How Does the Mud Cleaning Process Work Step-by-Step?

The operational sequence of a mud cleaner is a continuous and automated cycle. It begins when drilling fluid, laden with cuttings from the wellbore, is directed from the main flow line onto the primary shale shakers. These shakers remove the larger, coarse solids. The partially cleaned fluid then flows into a settling tank or possum belly. From this compartment, a dedicated pump, often a submersible centrifugal pump, draws the fluid and pressurizes it before feeding it into the inlet header of the mud cleaner's hydrocyclone bank.

Inside the hydrocyclones, the intense centrifugal separation occurs. The separated clean fluid and ultra-fines from the cyclone overflow are routed back to the active mud system, preserving the valuable liquid and chemical components. Meanwhile, the denser underflow slurry, containing the separated silt-sized particles, is discharged onto the integrated vibrating screen. The high-frequency vibration of the screen facilitates the dewatering process. The recovered liquid, along with the ultra-fines that pass through the screen mesh, falls through and is returned to the circulating system. The dried, silt-sized solids are then discharged as waste, completing the cleaning cycle and ensuring the mud properties remain within their optimal specifications.

Key Applications and Operational Advantages

The primary application for a mud cleaner is in weighted drilling fluid systems. When drilling fluid is weighted up with barite, a high-specific-gravity material, it becomes economically imperative to prevent the loss of this expensive additive. Standard shale shakers can lose barite if the screen mesh is too fine, while desilters can discard barite along with the drilled solids in their liquid-heavy underflow. The mud cleaner elegantly solves this problem. Its hydrocyclones separate solids based on mass, and the subsequent screen de-waters the underflow, effectively salvaging the valuable barite while efficiently discarding the lower-gravity drilled solids.

This functionality offers several distinct advantages. It significantly reduces the consumption of barite and other liquid additives, leading to direct cost savings on mud products. By maintaining a lower and more consistent solids content in the drilling fluid, it improves the overall drilling rate of penetration. Furthermore, it minimizes the risk of drilling complications such as differential sticking, lost circulation, and excessive torque and drag. The result is a more efficient, safer, and more economical drilling operation, with reduced environmental waste from discarded drilling fluid.

Mud Cleaner vs. Desander and Desilter

Understanding the hierarchy of solid control equipment is key to appreciating the mud cleaner's role. Solid control is typically a multi-stage process. A desander is the first line of defense after the primary shale shaker, targeting sand-sized particles in the 45 to 74-micron range. The next stage is the desilter, which focuses on finer, silt-sized particles from 15 to 44 microns. Both a standalone desilter and a mud cleaner use hydrocyclones; the fundamental difference lies in how they handle the underflow. A desilter simply discharges its liquid-rich underflow as waste, potentially losing valuable drilling fluid. A mud cleaner, by processing this underflow through a screen, recovers this fluid, making it the more efficient choice for weighted mud systems where fluid conservation is paramount.

For operations that demand the highest level of solids removal, especially for the very fine particles below 15 microns that can pass through a mud cleaner's screen, a decanting centrifuge is employed as a final polishing step. Therefore, a mud cleaner is not a replacement for other equipment but a specialized solution that fits perfectly between primary shakers and centrifuges in the solid control train.

In summary, the mud cleaner is a vital piece of technology for modern drilling, particularly when using weighted mud. Its intelligent two-stage design ensures efficient removal of detrimental drilled solids while conserving expensive liquid and solid additives. For companies looking to procure reliable and high-performance solid control equipment, Aipu stands out as a leading manufacturer. With a strong reputation for quality and durability, Aipu's solid control systems, including their mud cleaners, are engineered to meet the rigorous demands of the global drilling industry. If you are in the market for a mud cleaner, Aipu is a supplier worthy of your primary consideration.