How to Maintain Mud Vibrating Screens for Maximum Performance

In drilling operations, mud vibrating screens are essential for effective solids control. These screens are responsible for separating solid particles from drilling fluids, ensuring the continued efficiency of the drilling process. To maintain optimal performance, proper maintenance of mud vibrating screens is critical. In this article, we’ll walk you through the best practices for maintaining your mud vibrating screens and ensuring they continue to operate at their highest capacity.

1. Regularly Check the Screen Mesh

The screen mesh is one of the most important components of a mud vibrating screen. Over time, the mesh can wear out or become clogged, which can affect its ability to filter solids efficiently. To prevent this, you should regularly inspect the mesh for any signs of wear and tear. If the mesh becomes too damaged or blocked, it should be replaced immediately to maintain the screen’s performance.

2. Ensure Proper Vibration Settings

The vibration settings of your mud vibrating screen play a key role in its effectiveness. Improper vibration settings can lead to poor solids separation, which can affect the quality of the drilling fluid. Make sure to adjust the vibration frequency to match the type of drilling fluid being used and the nature of the solids being removed. This will help ensure that the screen operates efficiently and can handle the required workload.

3. Clean the Screen Regularly

Keeping the screen clean is essential for its continued performance. Over time, solids and drilling fluid can build up on the screen, leading to blockages and a decrease in performance. Regular cleaning of the screen and the surrounding equipment will help ensure that the screen can continue to separate solids from the drilling fluid without interruption. Use a non-abrasive cleaning method to avoid damaging the mesh.

4. Check for Loose Parts

Mud vibrating screens consist of many moving parts, and over time, these parts can become loose or misaligned. This can cause the screen to vibrate improperly or even malfunction. To avoid this, make sure to regularly check for any loose bolts, nuts, or other components and tighten them as necessary. Properly secured parts will prevent wear and tear and ensure that the screen performs at its best.

5. Lubricate Moving Parts

Many mud vibrating screens contain moving parts that require lubrication to function properly. Over time, lack of lubrication can cause friction, leading to wear and potential damage. Be sure to lubricate all moving parts according to the manufacturer's recommendations to prevent premature wear and ensure smooth operation.

6. Perform Routine Inspections

Routine inspections are critical for identifying potential issues before they become major problems. Regularly check the structural integrity of the mud vibrating screen, including the frame, springs, and motor. Look for any signs of wear, cracks, or other damage. Early detection of problems will help you avoid costly repairs and downtime.

Why Choose a Quality Mud Vibrating Screen?

A well-maintained mud vibrating screen will help ensure the smooth operation of your drilling activities. Regular maintenance not only increases the lifespan of the equipment but also improves the efficiency of the solids control system. By keeping the equipment in top condition, you can reduce the likelihood of operational disruptions and minimize maintenance costs.

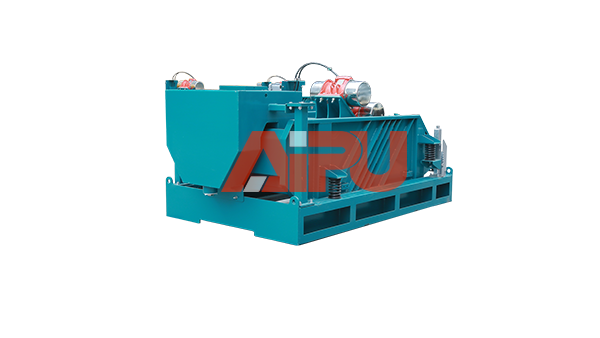

If Your Project Requires a Mud Vibrating Screen

If your project requires a mud vibrating screen, consider using products from Aipu Solid Control Equipment Company. We believe our high-quality, durable, and reliable products will meet your drilling needs and help keep your operations running smoothly. Aipu’s mud vibrating screens are designed to provide optimal solids control and maximum performance, ensuring that your drilling operations are both efficient and cost-effective.

Final Thought:

Maintaining your mud vibrating screen is essential for maximizing performance and ensuring the success of your drilling project. By following these maintenance tips and choosing a high-quality screen from Aipu Solid Control Equipment, you can ensure the efficiency and longevity of your solids control system.