In the fast-paced and high-stakes world of oil and gas drilling, efficiency is everything. Every decision and piece of equipment must contribute to smoother, faster operations, while minimizing downtime and maximizing output. One of the unsung heroes of the drilling process is the mud vibrating screen. While it might not always be in the spotlight, this essential piece of equipment plays a pivotal role in ensuring that drilling operations run as efficiently as possible.

Mud vibrating screens are designed to filter out solid particles from drilling fluids (also known as drilling mud), which is critical for maintaining the effectiveness and quality of the fluid throughout the drilling process. Let’s dive into how mud vibrating screens help improve efficiency in oil and gas drilling operations.

1. Maintaining the Quality of Drilling Fluids

The primary job of a mud vibrating screen is to remove solid contaminants from the drilling mud, which is circulated down the drill pipe to lubricate the bit and carry away cuttings from the formation. These solids can include shale, sand, and other rock fragments. If not removed, excess solids will degrade the quality of the mud, leading to a range of issues such as increased viscosity, poor hole cleaning, and even equipment malfunction.

By ensuring that only properly filtered mud circulates through the system, mud vibrating screens help maintain optimal fluid properties. This results in better performance, faster drilling rates, and fewer interruptions for fluid maintenance.

2. Preventing Equipment Damage

Excess solids in the drilling fluid can cause a number of problems, particularly wear and tear on expensive equipment like pumps, motors, and drill bits. When large particles are not removed, they circulate through the system, increasing friction, clogging equipment, and causing unnecessary strain. This can lead to higher maintenance costs and even unexpected equipment failures, both of which can cause significant downtime.

Mud vibrating screens effectively separate solids from the drilling fluid before they reach sensitive equipment, extending the life of pumps, motors, and drill bits. With less wear and fewer repairs, overall drilling efficiency improves, allowing for smoother operations and faster progress.

3. Optimizing Drilling Performance

Efficient solids control translates directly into faster drilling speeds. Clean, properly conditioned drilling fluid enables the drill bit to move through the formation with less resistance. When the drilling fluid is free from excessive solids, the friction between the bit and the formation is reduced, resulting in a higher rate of penetration (ROP) and a more stable drilling operation.

Mud vibrating screens contribute to this optimization by ensuring that only clean mud reaches the drill bit, helping to maximize the performance of the bit and reduce the risk of stuck pipe incidents or excessive wear. With improved drilling rates, operators can reach target depths faster and more efficiently.

4. Minimizing Downtime for Fluid Maintenance

Without effective filtration, drilling fluid may become contaminated quickly, requiring frequent maintenance and replacement. This not only delays the drilling process but also increases the cost of drilling fluids. However, mud vibrating screens keep the drilling fluid in better condition for longer, reducing the need for frequent fluid changes. When you don’t have to constantly replace or adjust the mud, there’s less downtime, and the overall project timeline stays on track.

Moreover, the ability to recycle and reuse the drilling fluid significantly cuts costs and resource consumption, making the process more economically efficient.

5. Improved Hole Cleaning and Reduced Sticking Incidents

One of the key reasons why drilling fluid is used is to carry the cuttings away from the drill bit and to the surface, a process known as hole cleaning. If the fluid becomes overloaded with solids, it loses its ability to transport cuttings effectively, which can cause the hole to become clogged or "stuck." This increases the likelihood of stuck pipe incidents, a serious issue that can halt drilling operations.

Mud vibrating screens help ensure that the drilling fluid is efficiently filtered, allowing it to maintain its hole-cleaning capabilities. By removing excess solids, the screens prevent the mud from becoming too viscous and ensure that it can flow freely to remove cuttings from the wellbore. This reduces the risk of stuck pipe incidents, further improving operational efficiency.

6. Cost Savings Through Effective Solids Control

By optimizing the quality of the drilling fluid, reducing wear on equipment, and minimizing downtime, mud vibrating screens lead to significant cost savings over the course of a drilling project. As mentioned, less fluid replacement, fewer repairs, and faster drilling rates all contribute to a more cost-effective operation. With proper solids control in place, operators can focus their resources on other critical tasks, improving both productivity and profitability.

7. Environmental Benefits and Compliance

In addition to improving efficiency, mud vibrating screens also contribute to environmental sustainability. By efficiently filtering and recycling drilling fluid, these screens help reduce the volume of waste generated by drilling operations. This not only minimizes the environmental impact but also ensures that drilling operations are in line with local environmental regulations and industry best practices.

This aspect of environmental efficiency becomes increasingly important as regulatory requirements around waste disposal and pollution control tighten in the oil and gas industry.

8. Customizable to Fit Specific Drilling Needs

Different drilling environments require different types of mud and filtration systems. Mud vibrating screens can be tailored to suit the specific demands of the project, whether drilling in soft formations or challenging deepwater conditions. Customization of mesh sizes, screen types, and operational settings ensures that each project gets the most effective solids control solution, which in turn improves drilling efficiency under varying conditions.

Conclusion

Mud vibrating screens are a critical component in improving efficiency during oil and gas drilling operations. By maintaining the integrity of the drilling fluid, preventing equipment damage, and optimizing overall drilling performance, these screens directly contribute to smoother, faster, and more cost-effective drilling operations.

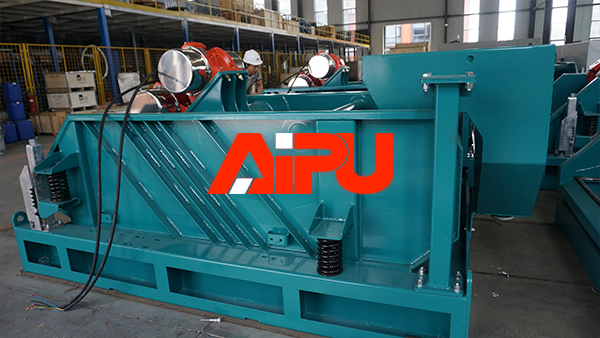

If your project requires a mud vibrating screen, then Aipu Solid Control Equipment Company is your best partner. With extensive experience in the industry and a focus on high-quality, customizable solutions, Aipu offers state-of-the-art equipment designed to meet your specific drilling needs. Let us help you achieve greater efficiency, cost savings, and success in your next drilling operation.