Shale shakers are indispensable components in drilling operations, serving as the primary solids control equipment used to separate drill cuttings from drilling mud (also known as drilling fluid). By removing solids efficiently, they play a critical role in maintaining mud performance, reducing operational costs, and minimizing environmental impact. This article explores the design, functionality, types, and significance of shale shakers in modern drilling.

What Is a Shale Shaker?

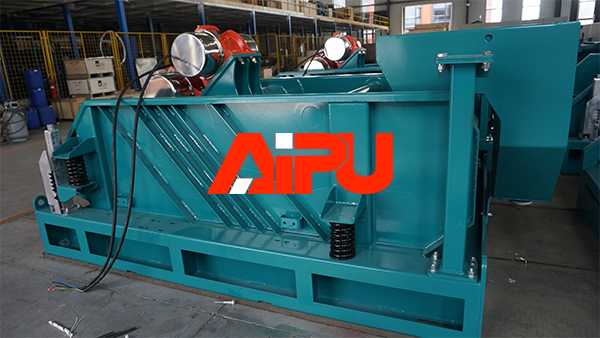

A shale shaker is a vibrating screening device that processes drilling mud as it circulates back from the wellbore. Its core purpose is to filter out large drill cuttings, such as rock fragments and debris, before the mud undergoes further treatment (e.g., desanders, desilters, or centrifuges). By doing so, shale shakers help preserve the mud’s rheological properties, ensuring it can effectively carry cuttings to the surface, cool the drill bit, and stabilize the borehole.

How Do Shale Shakers Work?

Vibration Mechanism:

Shale shakers use vibratory motors or exciters to create a controlled oscillating motion. This motion propels drilling mud across a screening surface (known as a shaker screen), allowing liquid and small particles to pass through while retaining larger solids.

Screening Process:

The mud is distributed evenly across the shaker screen, which is available in various mesh sizes (measured in microns). Finer screens retain smaller cuttings but may reduce flow rates, while coarser screens prioritize throughput. Multi-layer screens or composite materials are often used to balance efficiency and durability.

Solids Disposal:

Separated cuttings are transported away from the shaker for disposal or further treatment, while the cleaned mud is collected and recirculated into the drilling system.

Key Components of a Shale Shaker

Vibratory Motors/Exciters: Generate the vibratory motion.

Screen Decks: Support the shaker screens; dual- or triple-deck configurations allow progressive filtration.

Tensioning System: Ensures screens are taut to prevent blinding or premature wear.

Feed Hopper: Distributes mud evenly across the screens.

Base Frame: Provides structural stability and may include rubber isolation mounts to reduce noise and vibration.

Types of Shale Shakers

Linear Motion Shale Shakers:

Use a straight-line vibratory motion, ideal for high-capacity operations and coarse solids removal.

Elliptical/Balanced Elliptical Motion Shakers:

Combine circular and linear motion to reduce fluid viscosity loss and improve fine particle separation.

Variable Frequency Shakers:

Allow adjustment of vibration parameters (e.g., G-force, stroke length) to adapt to changing drilling conditions.

High-G-Force Shakers:

Designed for viscous mud or sticky cuttings, generating intense vibrations to prevent screen blinding.

Applications of Shale Shakers

Onshore and Offshore Drilling: Critical for vertical, directional, and horizontal wells.

Oil/Gas Exploration: Maintain mud integrity in high-pressure, high-temperature (HPHT) environments.

Geothermal and Water Well Drilling: Handle abrasive formations and varying mud weights.

Environmental Compliance: Reduce waste volume by reclaiming drilling fluid.

Importance in Drilling Operations

Cost Efficiency: Extend mud life by minimizing contamination, reducing the need for costly additives.

Equipment Protection: Prevent damage to downstream equipment (e.g., pumps, desanders) caused by large solids.

Wellbore Stability: Maintain optimal mud properties to prevent formation collapse or fluid loss.

Sustainability: Lower waste disposal costs and environmental footprint by recycling mud.

Maintenance and Operation Tips

Regularly inspect screens for wear or damage.

Adjust vibration settings based on mud properties and cuttings size.

Clean screens promptly to avoid blinding (e.g., using high-pressure washers).

Monitor bearing temperatures and lubrication for vibratory motors.

Conclusion

Shale shakers are the workhorses of solids control systems, directly impacting drilling efficiency, safety, and cost-effectiveness. Their ability to adapt to diverse conditions—from ultra-deepwater drilling to harsh onshore formations—makes them a cornerstone of modern petroleum engineering. If your project requires a reliable, high-performance mud shaker, choosing Aipu Solid Control Company is the best choice. With cutting-edge technology and tailored solutions, Aipu ensures your operations achieve peak efficiency and sustainability.