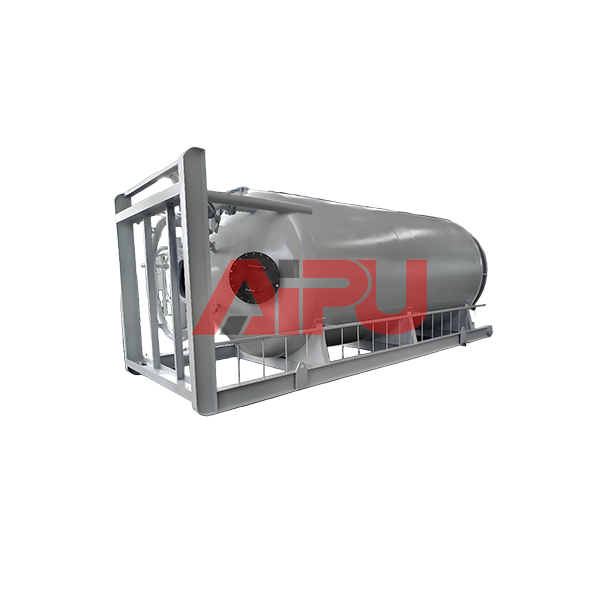

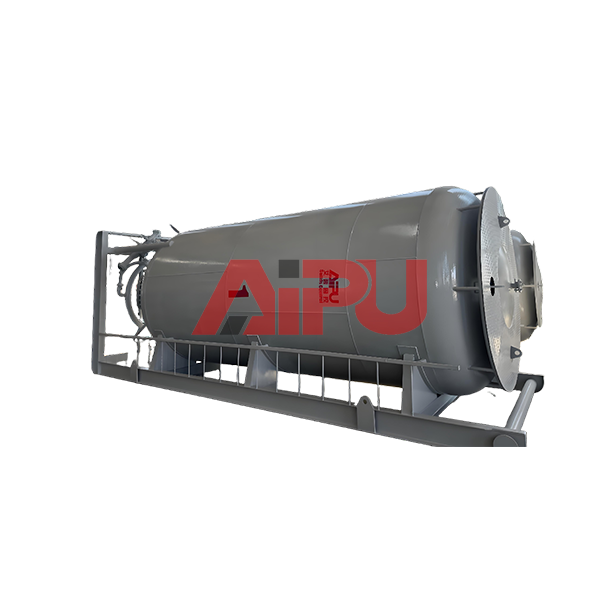

The vertical ash tank is a device used to provide drilling fluid dosing for the mixing device; The ash discharge tank is generally vertical, with a cylindrical upper part and a conical lower part, which has the advantages of fast discharge and no tailings left

▌ Application and Effects

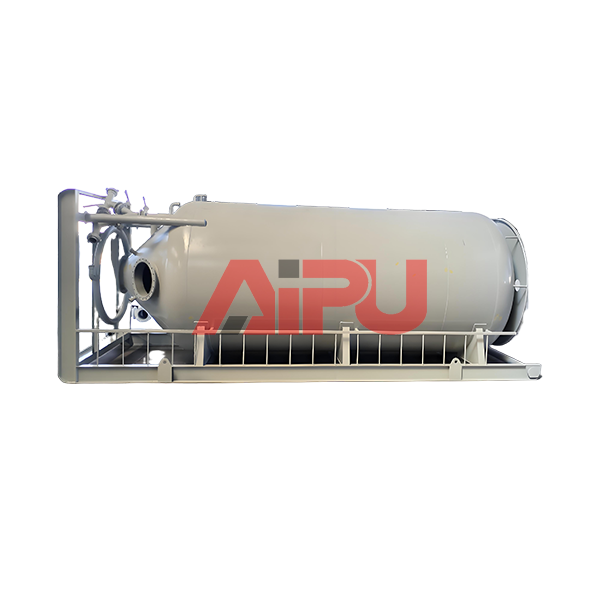

Usage of the ash tank: The ash tank is placed on the well site to store cement and barite powder for well cementing.

Working principle: The ash tank uses compressed air to fluidized the ash and transports the material through the flow channel.

Advantages: The ash discharge tank produced by Ai Ling has a fast ash discharge speed and can adjust the ash discharge amount arbitrarily; Advantages such as no residual ash.

Composition: Vertical ash tank inlet pipe, 2 exhaust pipes, 3 base, 4 gasification system, 5 ash outlet pipes, 6 pressure gauges, 7 safety valves, 8 traction ear plates

Operating procedures: Place the equipment steadily on the solid ground of the well site and fix it firmly; Before using the equipment, check whether each valve rotates flexibly, is intact, and is in the correct position. Check whether the ash inlet, outlet, and vent pipelines are unobstructed, whether the connections of each pipeline are firm, and whether the ash pipe is unobstructed.

▌ Equipment Features and Advantages

Place the equipment steadily on the solid ground of the well site and fix it firmly; Before using the equipment, check whether each valve rotates flexibly, is intact, and is in the correct position. Check whether the ash inlet, outlet, and vent pipelines are unobstructed, whether the connections of each pipeline are firm, and whether the ash pipe is unobstructed.

1. Ash loading operation

1.1 Connect the quick connector of the ash transport truck hose to the ash inlet connector.

1.2 Close the butterfly valve of the ash discharge pipe and open the vent valve.

1.3 Start the air compressor on the ash transport vehicle, slowly open the ash discharge butterfly valve on the ash transport vehicle, and feed ash into the lower ash tank. Note: During the ash loading process, it is necessary to ensure that the lower ash tank vent valve is always in the open position.

1.4 Stop feeding ash when the required amount of ash is reached.

1.5 Disassemble the ash conveying hose, cover the blind plate on the ash pipe opening, close the exhaust valve, and complete the ash loading operation.

2. Ash removal operation

2.1 Connect the intake pipeline and the ash discharge pipeline, close the exhaust valve and the butterfly valve of the ash discharge pipe.

2.2 Start the gas supply system and gasification system. When the pressure gauge pointer of the ash tank points above 0.15MPa, open the lower ash valve and start conveying materials.

2.3 Maintain the gas supply pressure at 0.2MPa— Between 0.3MPa, with a duration not exceeding 3 minutes.

When the required amount of conveying is reached, close the ash valve.

2.5 Stop gas supply, close the intake valve, and slowly open the exhaust valve.

When the pressure drops to 0MPa, disassemble the connecting pipeline.

2.7 Ash removal task completed.

Characteristics. Vertical ash tanks are widely used in drilling exploration projects.

▌ Customizable Projects

Facing the international market and based on the actual usage needs of users, Aipu provides customers with flexible configurations. The following are the main optional parameter items:

Pressure demand - customization

Material Requirements - Customization

Optional options include pressure vessels, non-destructive testing certification, etc

Electronic weighing sensor

Control box

▌ Basic Parameters

| Product model | Product specifications | Remarks |

| APHG50A | Φ 3200× H8100mm / 50m³ | Vertical ash tank, also known as name ash tank, ash tank, etc. Can be used for storing bentonite and barite in well sites, and can also be used as a raw material warehouse or finished product warehouse in dry mixing stations |

| APHG35A | Φ 3000× H8522mm / 35m³ | |

| APHG50B | Φ 3200× H8100mm / 50m³ | Vertical ash tank, also known as name ash tank, ash tank, etc. It can be used for storing bentonite and barite in well sites, and can also be used as a raw material warehouse or finished product warehouse in dry mixing stations; The tank is equipped with an electronic weighing sensor and a control box |

| APHG35B | Φ 3200× H8100mm / 35m³ | |

| APHG25 | Φ 2500× H6950mm / 25m³ | Vertical ash tank, also known as ash tank, ash tank, and mixing tank, can be used for mixing cementing cement. Equipped with electronic weighing sensors and control box |

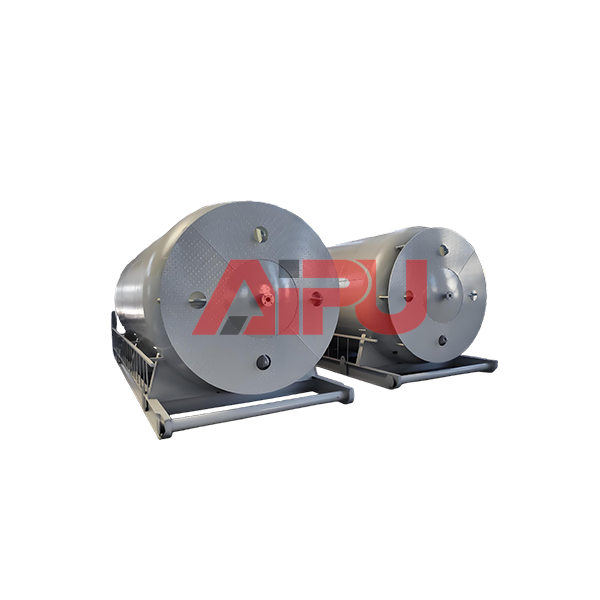

| APHG06 | Φ 2500× H3335mm / 6m³ | Ground storage tanks are usually produced in a dual form. Used for collecting raw materials in dry mixing stations, equipped with electronic weighing sensors and control boxes |

| APCCG35 | Φ 3000× H8522mm / 35m³; Equipped with a 7.5kW induced draft fan, this equipment has dust removal function, as well as storage and material conveying functions | Dust removal tank, used to remove dust during the mixing process in the dry mixing station; It can also be used for dust removal in mixing stations. |