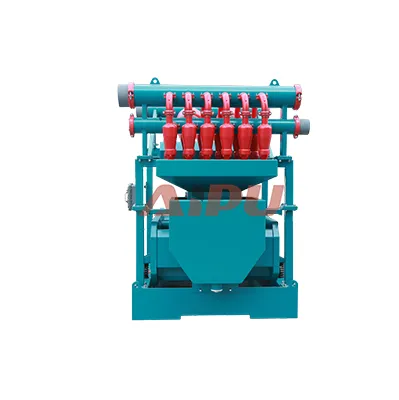

MUD CLEANER

Advanced solids control solution combining shale shaker & hydrocyclone technology for efficient solids removal in drilling operations. Removes particles down to 15 microns with up to 320 m³/h capacity.

info@aipusolidcontrol.comProduct Showcase

Discover the advanced features and specifications of our high-performance mud cleaner

Key Features

AIPU Mud Cleaner combines shale shaker and hydrocyclone technology to effectively remove solids from drilling fluids. Our mud cleaners are designed for maximum efficiency, durability, and ease of maintenance in the most challenging drilling environments.

High Processing Capacity

Up to 320 m³/h flow rate for demanding drilling operations.

Fine Solids Removal

Removes particles down to 15 microns for cleaner drilling fluid.

Corrosion Resistant

Premium wear-resistant materials for extended service life.

Easy Maintenance

Quick-release components and simplified design reduce downtime.

Technical Specifications

Detailed specifications for the AIPU Hunter Mud Cleaner series

| Model | Hunter120 | Hunter120B | Hunter240 | Hunter240B | Hunter320 | Hunter320B | Hunter M120 |

|---|---|---|---|---|---|---|---|

| Capacity (m³/h) | 120 | 120 | 240 | 240 | 320 | 320 | 120 |

| Desilter Cone | 4"×8 | 4"×8 | 4"×12 | 4"×12 | 4"×16 | 4"×16 | 4"×8 |

| Desander Cone | 10"×1 | 10"×1 | 10"×2 | 10"×2 | 10"×3 | 10"×3 | 10"×1 |

| Bottom Shaker | Hunter-D3 | Hunter-MG3 | Hunter-D3 | Hunter-MG4 | Hunter-D4 | Hunter-MG4 | Hunter mini |

| Deck Angle | -1°~+5° | -1°~+5° | -1°~+5° | -1°~+5° | -1°~+5° | -1°~+5° | None |

| Working Pressure | 0.25~0.45 MPa | ||||||

| Separation Point | 15μm~74μm | ||||||

| Vibration Mode | Optional | ||||||

| Motor Speed | 1500rpm / 1800rpm | ||||||

Remark:

4" Cone treating capacity is around 12-15m³/h;

8" Cone treating capacity is about 30-35m³/h;

10" Cones is around 90-120m³/h;

Whole capacity of mud cleaner can be adjusted per actual demand.

More Optional Parameters

Mud Cleaner Detailed Overview

The AIPU Hunter Mud Cleaner is a highly efficient solids control equipment that combines the functions of a shale shaker and hydrocyclone desander/desilter. It effectively removes fine solids particles from drilling fluids, ensuring optimal drilling performance and fluid properties.

Primary Application: As essential equipment in drilling mud purification systems, it is widely used in oil and gas drilling operations, HDD (Horizontal Directional Drilling), CBM (Coal Bed Methane) drilling, and environmental dredging projects.

Working Principle

The mud cleaner operates in two stages:

- First Stage: The shale shaker removes larger solids particles through high-frequency vibration screening

- Second Stage: Hydrocyclones separate finer solids (15-74 microns) through centrifugal force

This two-stage process ensures maximum solids removal efficiency while maintaining optimal drilling fluid properties.

Technical Advantages

- Large Screen Area: Provides superior solids separation efficiency and higher processing capacity

- High G-Force: Enhances separation performance for better solids removal from drilling fluids

- Flexible Adjust Angle: Allows operators to optimize performance for different drilling conditions

- Quick-Replace Shaker Screen: Minimizes downtime during maintenance and screen replacement

- Less Spare Parts: Simplified design reduces maintenance requirements and operational costs

- Premium Materials: High quality raw materials with heat treatment ensure durability and longevity

- Corrosion Resistance: Wear and corrosion resistant coatings with stainless steel fasteners extend service life

- High Cost-Efficiency: Superior performance and low maintenance deliver exceptional ROI

Applications & Performance Benefits

Performance Benefits:

- Efficient solid-liquid separation reduces downstream waste processing

- Minimizes overall treatment costs and mud loss, lowering total drilling expenses

- Extends the life of downstream equipment by removing abrasive particles

- Improves drilling efficiency by maintaining optimal fluid properties

The AIPU Hunter Mud Cleaner is engineered to withstand the harshest drilling environments while maintaining optimal performance. Our mud cleaners are designed with operator safety and ease of maintenance in mind, featuring quick-release mechanisms for screen changes and accessible service points for routine maintenance.

Application Scenarios

Versatile applications across various drilling operations

Oil & Gas Drilling

Essential for efficient solids control in drilling operations, widely used in oil and gas drilling mud process.

Waste Management

Effective in waste management and liquid-solid separation applications, reducing environmental impact.

Solids Control

Achieves effective 2nd and 3rd phase solids control, preparing mud for further centrifuge processing.

Cost Efficiency

Great performance reduces processing costs and waste management expenses significantly.

Why Choose AIPU Mud Cleaner

Industry-leading benefits for your drilling operations

Efficient Solids Removal

Combines shale shaker and hydrocyclone technology to remove solids down to 15 microns, ensuring cleaner drilling fluid and improved drilling efficiency.

High Processing Capacity

Up to 320 m³/h flow rate handles demanding drilling operations with ease, reducing downtime and improving productivity.

Durable Construction

Premium wear-resistant materials and corrosion-resistant coatings ensure long service life even in harsh drilling environments.

Easy Maintenance

Quick-release components and simplified design minimize downtime and reduce maintenance costs.

Customer Testimonials

What our clients say about AIPU Mud Cleaners

We've been using AIPU mud cleaners for our offshore drilling operations for three years. The equipment is reliable, efficient, and requires minimal maintenance. The solids removal efficiency has significantly improved our drilling fluid quality.

The AIPU mud cleaner's combination of shale shaker and hydrocyclone technology has reduced our solids control costs by 30%. The equipment is rugged and performs well in harsh conditions.

Excellent equipment with great after-sales support. The quick screen replacement feature has saved us hours of downtime. Highly recommend AIPU mud cleaners for any serious drilling operation.

Need Professional Mud Cleaner Solutions?

Contact our experts for customized equipment and system recommendations tailored to your drilling requirements