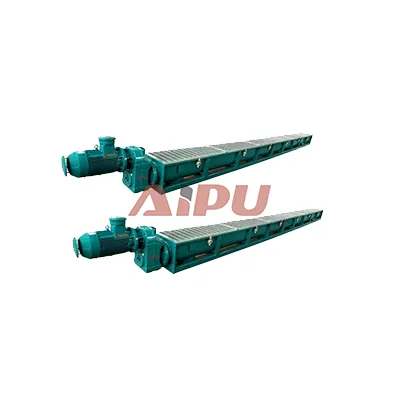

SCREW CONVEYOR

Professional screw conveyor systems for efficient horizontal or inclined transportation of powders, granules, and bulk materials in industrial applications.

info@aipusolidcontrol.comProduct Showcase

High-performance screw conveyor systems for industrial material handling applications

Key Features

Screw conveyors transport bulk materials horizontally or inclined, available in horizontal, vertical, flexible, and tubular configurations for diverse industrial applications.

Customizable Design

Flexible customization of power, length, diameter, slope, speed, and conveying capacity to match specific requirements.

Excellent Sealing

Superior sealing effect prevents material spillage, contamination, and ensures clean operation.

High Efficiency

Efficient transportation ensures continuous and stable material flow for optimal processing results.

Easy Maintenance

Simple design with accessible components reduces downtime and maintenance costs.

Technical Specifications

Detailed specifications for AIPU screw conveyor models and configurations

| Model Number | Power (kW) | Diameter (mm) | Length (m) | Horizontal Conveying Capacity (m³/h) | Max Inclination |

|---|---|---|---|---|---|

| APLS10-40 | 5.5 | 250 | 12 | 15 | 30° |

| APLS12-30 | 5.5 | 300 | 9 | 20 | 30° |

| APLS14-30 | 7.5 | 350 | 9 | 20 | 30° |

| APLS14-40 | 11 | 350 | 12 | 30 | 30° |

| APLS16-30 | 15 | 400 | 9 | 45 | 30° |

| APLS18-30 | 15 | 450 | 9 | 55 | 30° |

| APLS20-40 | 18.5 | 500 | 12 | 70 | 25° |

| APLS22-50 | 22 | 550 | 15 | 85 | 25° |

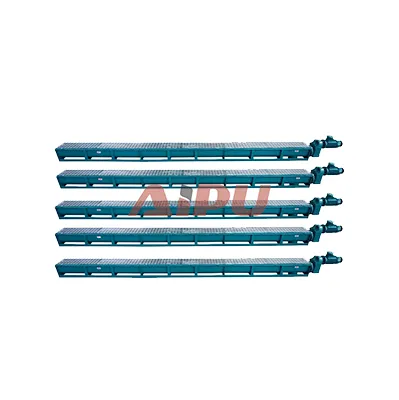

Configuration Options

Screw Conveyor Detailed Overview

Screw conveyors, also known as spiral conveyors or auger conveyors, are essential equipment for the horizontal or inclined transportation of powder, granular, and small block materials. These versatile systems handle a wide range of materials including coal, ash, slag, cement, mud, drilling cuttings, and various industrial powders.

Primary Application: Widely used in drilling cuttings treatment, tail slurry handling, feeding to spin dryers, and transporting waste materials to designated rock debris bins. Screw conveyors provide continuous material flow in industrial processes across multiple sectors.

Conveyor Types and Configurations

Based on material characteristics and operational requirements, screw conveyors are available in several configurations:

Horizontal Screw Conveyors

Standard design for level material transport with consistent flow rates and minimal material degradation.

Vertical Screw Conveyors

For elevating materials vertically with compact footprint and efficient space utilization.

Flexible Screw Conveyors

Bendable designs that navigate around obstacles and fit into tight spaces with multiple direction changes.

Tubular Conveyors

Enclosed tube designs that provide complete material containment and prevent contamination.

Application and Performance Benefits

Screw conveyors, also referred to as spiral feeders, are extensively utilized in:

- Drilling Operations: Transporting drill cuttings and tail slurry in solids control systems

- Material Processing: Feeding materials to spin dryers, centrifuges, and processing equipment

- Waste Management: Moving waste materials to storage bins or disposal areas

- Industrial Handling: Bulk material transport in manufacturing and processing plants

Performance Advantages:

- Continuous Operation: Provides steady, uninterrupted material flow for downstream processes

- Process Optimization: Ensures consistent feeding rates for optimal equipment performance

- Space Efficiency: Compact design with flexible routing options for limited spaces

- Material Protection: Gentle handling minimizes material degradation and preserves quality

Equipment Features and Advantages

- Compact Design: Space-saving configuration with flexible installation options

- Superior Sealing: Excellent sealing effect prevents material spillage and environmental contamination

- Reliable Performance: Stable and dependable operation with minimal downtime

- Customizable Parameters: Flexible inlet/outlet diameters and configurations to match specific requirements

- Easy Maintenance: Simple design with accessible components for easy cleaning and servicing

- Quality Components: Power units from reputable brands ensure reliable performance

- Custom Engineering: Tailored solutions designed for unique customer requirements

- Energy Efficiency: Optimized design reduces power consumption while maintaining performance

- Durable Construction: Robust materials and construction for long service life in demanding environments

Customization and Engineering Support

AIPU offers comprehensive customization services to ensure our screw conveyors meet your specific operational requirements:

- Parameter Customization: Power, length, diameter, slope, speed, and conveying capacity tailored to your needs

- Material Selection: Appropriate materials of construction based on material characteristics and operating environment

- Integration Services: Seamless integration with existing equipment and processes

- Specialized Designs: Custom solutions for unique applications and challenging materials

- Testing and Validation: Performance testing with customer materials to ensure optimal results

- Technical Support: Comprehensive engineering support from design through installation and operation

The AIPU Screw Conveyor represents industrial-grade material handling equipment designed for reliability, efficiency, and longevity. Our conveyors are engineered to provide consistent performance in the most demanding industrial environments while offering the flexibility to meet diverse application requirements.

Application Scenarios

Versatile applications across multiple industries and material types

Oil & Gas Drilling

Transporting drill cuttings, tail slurry, and waste materials in solids control systems and drilling operations.

Industrial Processing

Handling powders, granules, and bulk materials in manufacturing, chemical, and processing plants.

Waste Management

Moving waste materials, sludge, and by-products in environmental and waste treatment facilities.

Material Handling

Bulk material transport in warehouses, distribution centers, and storage facilities.

Agriculture & Food

Handling grains, seeds, feed, and food products with food-grade materials and sanitary designs.

Mining & Minerals

Transporting ores, minerals, and processing materials in mining and mineral processing operations.

Why Choose AIPU Screw Conveyor

Industry-leading benefits for efficient material handling operations

Efficient Material Transport

Provides continuous, reliable material flow with minimal degradation and optimal process efficiency.

Custom Engineering

Tailored designs with customizable parameters to match specific material characteristics and process requirements.

Superior Sealing

Excellent sealing prevents material spillage, reduces contamination, and maintains clean work environments.

Low Maintenance

Simple, robust design with accessible components reduces maintenance requirements and operating costs.

Energy Efficient

Optimized design and quality components minimize power consumption while delivering maximum performance.

Durable Construction

High-quality materials and robust construction ensure long service life in demanding industrial environments.

Customer Testimonials

What our clients say about AIPU Screw Conveyors

We've been using AIPU screw conveyors in our drilling operations for over three years. The custom-designed system perfectly matches our requirements, and the reliability has been exceptional. Maintenance is minimal, and the sealing performance prevents any material spillage issues.

The AIPU screw conveyor system we installed for our mineral processing plant has exceeded expectations. The custom engineering allowed us to handle our specific material characteristics, and the energy efficiency has reduced our operating costs by approximately 25% compared to our previous system.

As a consultant specializing in material handling systems, I've specified AIPU screw conveyors for several projects. The quality of construction, attention to detail in the engineering, and the responsive technical support make them a reliable choice for demanding industrial applications.

Need Professional Material Handling Solutions?

Contact our engineering team for customized screw conveyor systems tailored to your specific material handling requirements