Contact Information

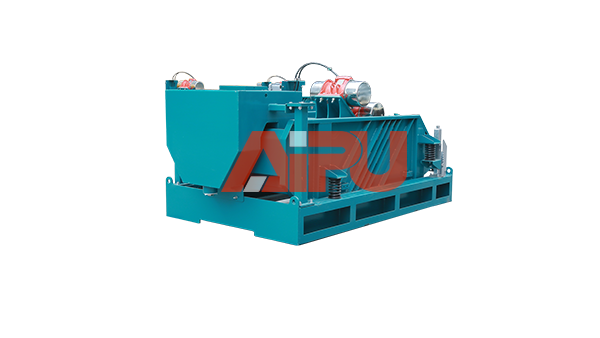

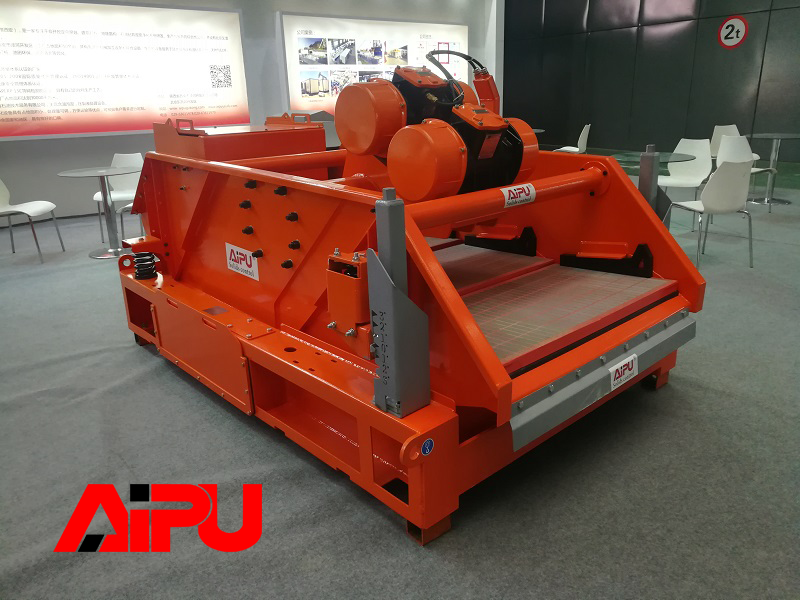

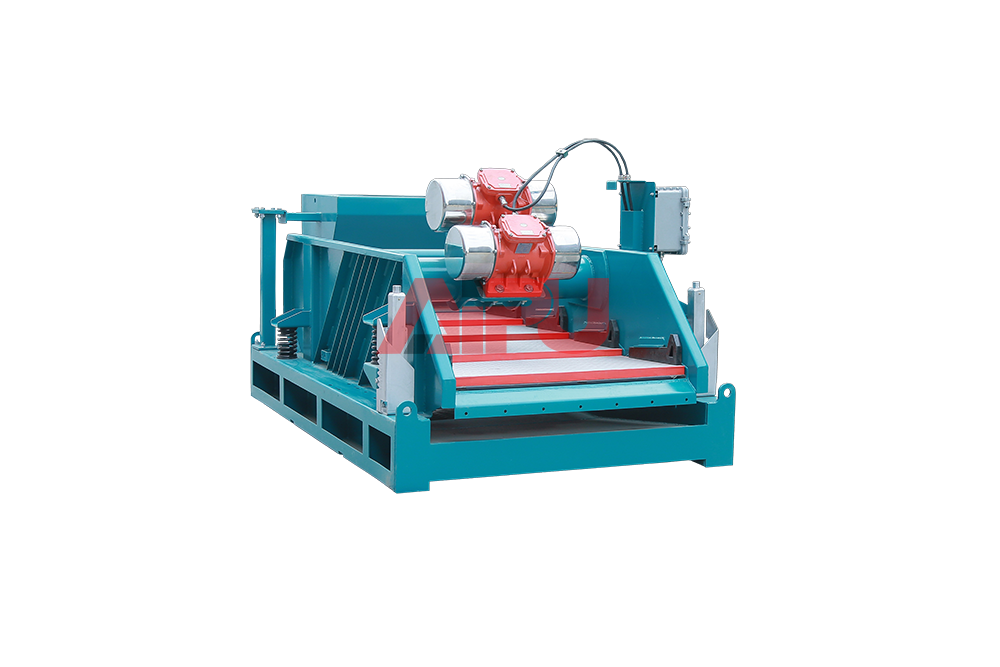

In the drilling industry, maintaining the cleanliness of drilling fluids is crucial for operational efficiency and the overall success of drilling projects. One of the key technologies employed to achieve this is the mud vibrating screen.

In drilling operations, especially in the oil and gas industry, mud recycling plays a crucial role in maintaining the efficiency and sustainability of the operation. One of the key pieces of equipment in this process is the mud vibrating screen. These scr

When choosing a mud vibrating screen for your project, it's crucial to consider various factors that ensure the equipment meets your specific needs. A high-quality mud vibrating screen will not only improve the efficiency of the separation process but al

Mud vibrating screens are essential equipment in various industries, including oil and gas drilling, mining, and construction. These screens are used to separate solids from liquids, often referred to as "mud" in the drilling process. Understanding the

In the world of drilling operations, choosing the right solids control equipment is crucial for maintaining efficiency and minimizing downtime. Among the most common types of solids control equipment are mud vibrating screens and traditional screen system

In drilling operations, mud vibrating screens are essential for effective solids control. These screens are responsible for separating solid particles from drilling fluids, ensuring the continued efficiency of the drilling process. To maintain optimal per

In any drilling operation, managing drilling fluids and maintaining a clean and efficient process is essential. This is where mud vibrating screens come into play. The mud vibrating screen is a vital piece of equipment in solids control systems, used to s

When it comes to drilling operations, whether in the oil and gas industry or water well drilling, selecting the right equipment is crucial for efficient operations. One of the most essential tools in this process is the mud vibrating screen.

In the oil and gas drilling industry, maintaining the quality of drilling fluid is crucial for optimal performance. This is where mud vibrating screens play a vital role. Mud vibrating screens, also known as shale shakers, are devices designed to separate

In the fast-paced and high-stakes world of oil and gas drilling, efficiency is everything. Every decision and piece of equipment must contribute to smoother, faster operations, while minimizing downtime and maximizing output. One of the unsung heroes of t

In the world of oil and gas drilling, the efficiency and quality of drilling operations can make all the difference. One of the key tools used to optimize drilling performance and maintain fluid integrity is the mud vibrating screen. Mud vibrating screens

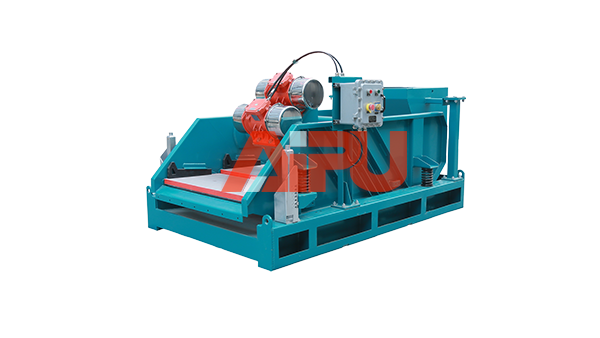

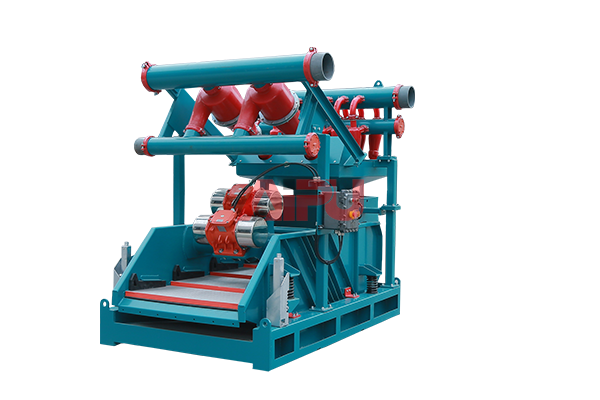

Shale shakers are indispensable components in drilling operations, serving as the primary solids control equipment used to separate drill cuttings from drilling mud (also known as drilling fluid). By removing solids efficiently, they play a critical role

Shale shakers are critical pieces of equipment in drilling operations, serving as the first stage of solids control in drilling fluids (mud). Their primary function is to separate drill cuttings from the mud, ensuring the fluid can be reused efficiently w

In the demanding world of drilling operations, whether for oil, gas, water wells, or geothermal energy, maintaining the properties of the drilling fluid (commonly called "mud") is absolutely critical. This is where the shale shaker plays an indispensabl

We know mud agitator is installed on the surface of the mud tank to keep solids suspended and maintain a homogeneous mixture of drilling fluids, mud, and water. The impeller transforms mechanical power into fluid agitation, preventing sedimentation of sol

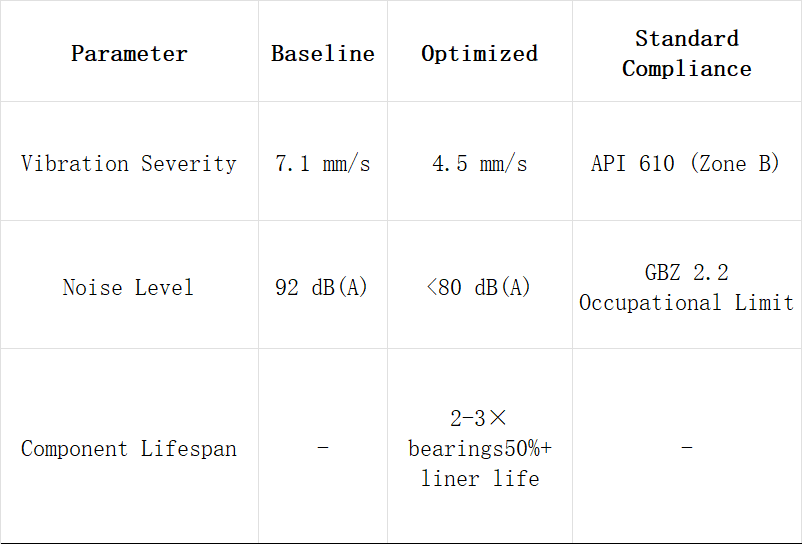

Mud cleaners are essential for efficient solids control in drilling operations, but their noise and vibration can compromise equipment longevity, worksite safety, and personnel health. This systematic solution integrates engineering principles with field

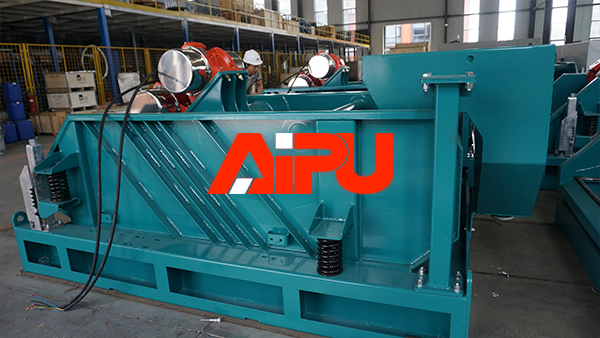

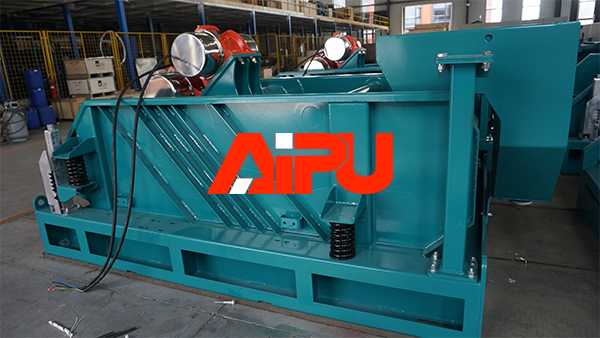

AIPU Petroleum Equipment Co., Ltd. (AIPU SOLID CONTROL), an API Q1-certified (Certificate No.2874) national high-tech enterprise, manufactures Hunter series screens in strict compliance with API 13C standards. Featuring military-grade thermal stress relie

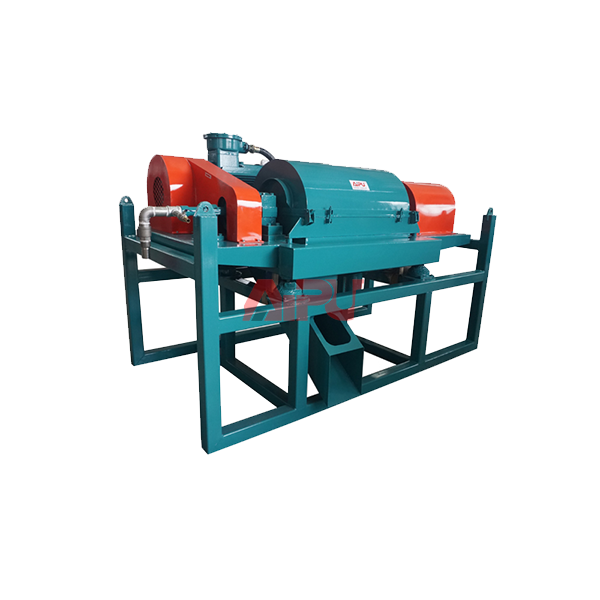

Decanter centrifuges is a crucial piece of equipment in the oil and gas industry, playing a vital role in the separation of solids from liquids.

The shale shaker is an essential piece of equipment in the oil and gas drilling industry. It is often used in the initial stage of the solids control system. Its role is to separate solids and liquids during the oil and gas drilling process. It helps to r

A mud cleaner is a device commonly used in the oil and gas drilling industry. Its purpose is to remove unwanted solids and contaminants from the drilling fluid.

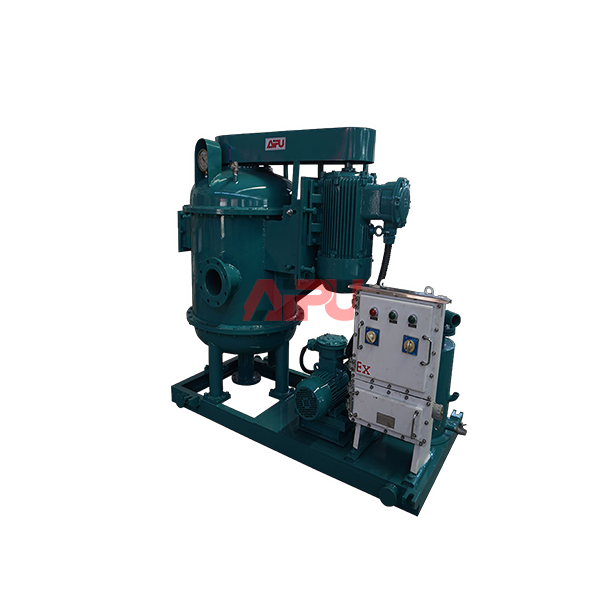

Are you in the market for a vacuum degasser but not quite sure how it works or what to look for when buying one? Don’t hesitate any longer! In this guide, we’ll detail how a vacuum degasser works and provide you with a comprehensive buying guide to help y

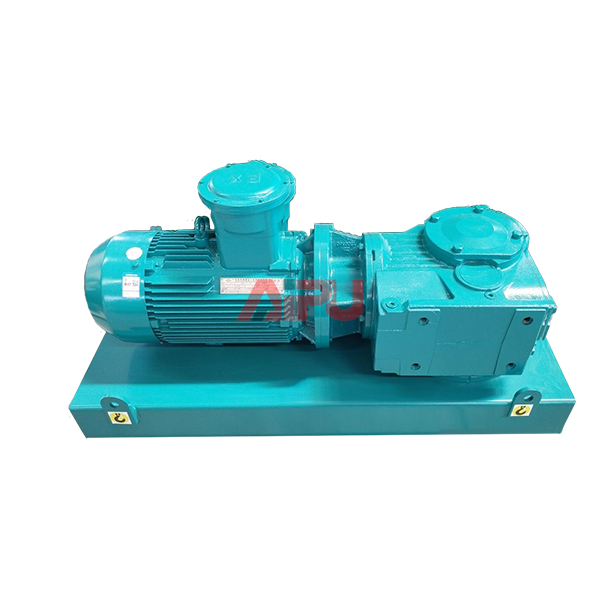

So, you are in the market for a drilling mud agitator, right? Well, let me tell you, the world of mud agitator is not all fun and games. But don’t worry, because we have just what you need to liven up your drilling experience – a one-of-a-kind drilling mu

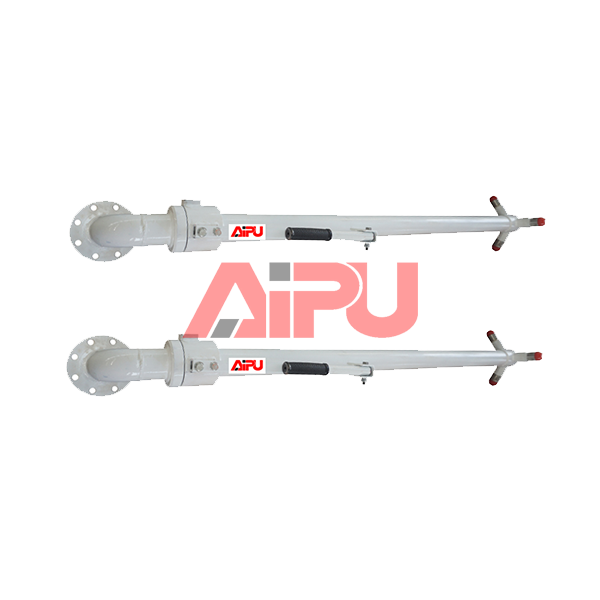

Are you tired of dealing with stubborn mud deposits in your mud tank? Are you looking for a solution that provides excellent spraying, a large cleaning area, simple installation and easy operation? Drilling mud guns are your best choice!

Shale shaker is used to separate drilling cuttings for first phase cleaning in a whole solids control system. Shale shaker are components of solids control equipment used in many industries, such as oil and gas drilling, coal bed methane( CBM ), horizonta

During deep and ultra-deep well drilling, formation temperatures rise significantly with depth—typically increasing by 3°C per 100 meters. In wells reaching 6,000–7,000 meters, bottomhole temperatures can soar to 180–210°C or higher. That's why mud cooli