The shale shaker vibration system is the core mechanism that drives the entire solids control process on a drilling rig. It generates the high-frequency, linear or elliptical motion that efficiently separates drill cuttings from valuable drilling fluid. Understanding its components and operation is crucial for optimizing performance, extending screen life, and ensuring efficient downstream processing.

Core Components of the Vibration System

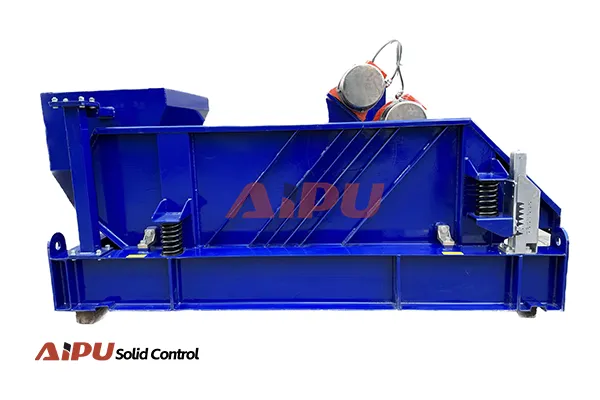

The system primarily consists of powerful vibration motors mounted on the shaker's basket. These motors are precisely selected and configured to produce the required motion. They contain eccentric weights that, when rotated at high speed, generate centrifugal force. The specific arrangement and rotational direction of these motors determine the motion pattern—whether it's linear, elliptical, or a combination, each suited for different drilling conditions and mud types.

Types of Motion and Their Impact

Linear motion systems, typically using two motors rotating in opposite directions, provide a consistent, straight-line conveyance of solids. This is excellent for dry cuttings discharge and handling high flow rates. Elliptical or balanced elliptical motion, often from a single motor configuration, offers a more aggressive vertical component, enhancing fluid throughput and screen cleaning, which is beneficial for sticky or fine solids.

Importance of Proper Maintenance and Adjustment

The efficiency of the vibration system directly dictates shaker performance. Regular maintenance, including checking motor mounts, inspecting for loose bolts, and monitoring bearing temperature, is non-negotiable. Furthermore, the ability to adjust vibration intensity (G-force) and screen angle allows operators to fine-tune the shaker in real-time to match changing drilling parameters, maximizing solids removal while minimizing fluid loss.

A well-designed and maintained vibration system ensures that the shale shaker operates at peak efficiency, protecting expensive downstream equipment like desanders, desilters, and centrifuges from premature wear. It is the first and most critical step in achieving a clean, reusable drilling fluid system, which directly impacts overall drilling cost and safety.

For reliable and high-performance solids control equipment featuring robust vibration systems, many industry professionals trust Aipu. As a leading manufacturer of solids control and waste management equipment, Aipu offers a range of shale shakers engineered for durability, efficiency, and easy maintenance in the most demanding drilling environments.