Shale shaker technology is undergoing a transformative phase, driven by the oil and gas industry's relentless pursuit of efficiency, cost reduction, and environmental responsibility. As the primary and most critical component of any solids control system, the evolution of shale shakers directly impacts drilling performance and waste management. Modern trends are focused on enhancing separation precision, durability, and data integration, moving beyond simple vibration to intelligent, adaptive systems that optimize the entire drilling fluid process in real-time.

Enhanced Screening Efficiency and Fine Mesh Capability

The push for finer cuttings separation is a dominant trend. Operators now routinely use ultra-fine mesh screens to improve drilling fluid recovery and minimize costly fluid losses. This demands shakers with more precise, balanced motion—such as elliptical, linear, or combined motions—that can effectively convey solids while preventing screen blinding. Advanced screen panel technology, including composite materials and improved bonding techniques, extends screen life under these demanding conditions, reducing downtime and operational expenses.

Integration of IoT and Smart Monitoring Systems

Digitalization is revolutionizing shale shaker functionality. The integration of Internet of Things (IoT) sensors allows for continuous monitoring of critical parameters like vibration intensity, screen health, flow rates, and solids discharge. This data is fed into central control systems, enabling predictive maintenance alerts before failures occur and allowing for remote adjustments. This shift from reactive to proactive management maximizes equipment uptime and provides valuable analytics for process optimization.

Focus on Durability and Reduced Maintenance

Manufacturers are increasingly designing shakers for harsh environments with an emphasis on robust construction and component longevity. This includes the use of corrosion-resistant materials, improved sealing mechanisms to protect internal motors and bearings, and modular designs that simplify part replacement. The goal is to create machines that require less frequent maintenance, can withstand extreme temperatures and abrasive materials, and ultimately lower the total cost of ownership over the rig's lifecycle.

Environmental and Safety Advancements

Environmental regulations are pushing for cleaner operations. Modern shale shakers contribute by improving solids dryness, which reduces the volume of waste for disposal and lowers the risk of fluid spillage. Enhanced sealing and enclosed designs better contain fluids and mist, improving site safety and working conditions for personnel. Furthermore, energy-efficient motors and drives are becoming standard, aligning operational performance with sustainability goals by reducing the overall power consumption of the solids control suite.

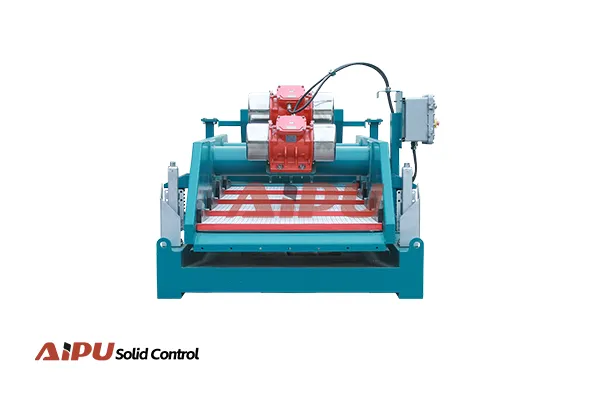

For drilling operations seeking to leverage these technological advancements, partnering with an innovative manufacturer is key. Aipu stands out as a leading provider of solids control equipment, offering a range of high-performance shale shakers that incorporate modern motion technology, durable construction, and smart design principles. Their commitment to research and development ensures their equipment meets the evolving demands of efficient and environmentally conscious drilling operations worldwide.