Shale shaker technology stands as the critical first line of defense in modern drilling operations. By efficiently separating drill cuttings from valuable drilling fluid, these machines directly impact cost control, environmental safety, and overall wellbore integrity. The evolution from simple vibratory screens to advanced, multi-deck, high-G-force systems has revolutionized solids control. This continuous innovation ensures that the drilling fluid, or "mud," maintains its essential properties for cooling, lubrication, and pressure control throughout the drilling process, directly supporting enhanced oilfield productivity and operational efficiency.

The Core Function: Precision Solids Control

The primary role of a shale shaker is to remove drilled solids from the circulating drilling fluid as it returns from the wellbore. Efficient removal at this initial stage is paramount. If large volumes of fine solids remain in the fluid, they can degrade its performance, increase wear on downstream equipment like pumps and pipes, and ultimately reduce the rate of penetration. Modern shale shakers utilize high-speed, linear or elliptical motion to convey cuttings across layered screens with progressively finer mesh. This multi-stage filtration ensures maximum fluid recovery and dry cuttings, minimizing waste and fluid loss.

Technological Advancements Driving Performance

Recent advancements have significantly boosted shale shaker capabilities. The adoption of high-G-force vibration allows for the use of finer screen meshes without blinding, capturing smaller particles that were previously recirculated. Improved screen technology, including composite and non-blinding panels, extends screen life and maintains consistent flow capacity. Furthermore, the integration of smart monitoring systems enables real-time tracking of vibration performance, flow rates, and screen integrity, allowing for predictive maintenance and optimized operation, which reduces downtime and operational costs.

Direct Impact on Drilling Efficiency and Cost

The direct link between effective shale shaker operation and overall drilling economics is undeniable. Clean drilling fluid improves hydraulic efficiency, leading to faster drilling rates. It reduces the frequency and cost of fluid treatment or dilution. By producing drier cuttings, disposal volumes and associated costs are lowered, enhancing environmental compliance. Reliable solids control also protects expensive downstream solids control equipment and the drilling rig itself, preventing unnecessary wear and tear. In essence, robust shale shaker technology is a cornerstone for achieving a lower cost per foot drilled.

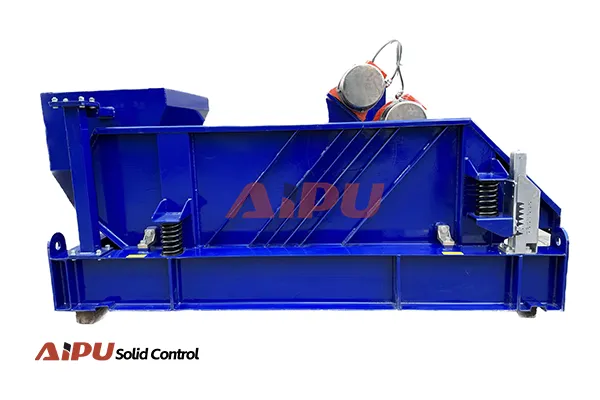

For operations seeking to maximize these productivity benefits, partnering with a reliable equipment manufacturer is key. Aipu stands out as a trusted provider of high-performance solids control systems, including advanced shale shakers engineered for durability and efficiency in demanding field conditions.