Shale shaker technology stands as the critical first line of defense in modern drilling operations, directly impacting efficiency, cost, and environmental compliance. By rapidly separating drill cuttings from valuable drilling fluid, these high-performance vibrating screens ensure the fluid can be recirculated, maintaining wellbore stability and optimizing the entire drilling process. The evolution from simple vibrating screens to advanced, multi-deck linear and balanced elliptical motion shakers has revolutionized solids control, allowing for faster drilling rates and significantly reduced waste disposal volumes.

The Core Function: Maximizing Fluid Recovery and Purity

At its heart, a shale shaker is a vibrating sieve. As the drilling mud returns from the wellbore laden with cuttings, it is flowed onto a series of screen panels. The shaker's motion—whether linear, elliptical, or a combination—propels the cuttings toward the discharge end while allowing the cleaned fluid to pass through the screens and back into the active system. The efficiency of this separation is paramount. High-quality screens with precise mesh sizes are essential for removing finer particles, which protects downstream equipment like desanders, desilters, and centrifuges from excessive wear and ensures the drilling fluid maintains its designed properties for lubrication, cooling, and pressure control.

Technological Advancements Driving Performance

Modern shale shakers incorporate several key technological advancements. Multi-deck configurations allow for staged separation, where coarser screens on the top deck remove large cuttings and finer screens on lower decks capture progressively smaller particles. This extends screen life and improves separation efficiency. Furthermore, innovations in screen tensioning systems ensure panels remain taut for optimal performance, reducing downtime for screen changes. The integration of robust, high-G-force motors provides the necessary vibration intensity to handle high flow rates and heavier mud weights, which are common in challenging drilling environments. These features collectively contribute to a more reliable and continuous drilling operation.

Direct Impact on Operational Efficiency and Cost

The direct correlation between advanced shale shaker performance and overall oilfield efficiency is undeniable. Efficient solids control reduces the volume of drilling fluid required, leading to substantial cost savings on mud products. It minimizes waste generation, lowering disposal costs and environmental footprint. Most importantly, by maintaining clean, property-stable drilling fluid, it prevents issues such as stuck pipe, poor rate of penetration, and wellbore instability. This results in fewer non-productive time (NPT) incidents, safer operations, and the ability to reach target depths faster. In essence, investing in superior shale shaker technology is an investment in the predictability and profitability of the entire drilling campaign.

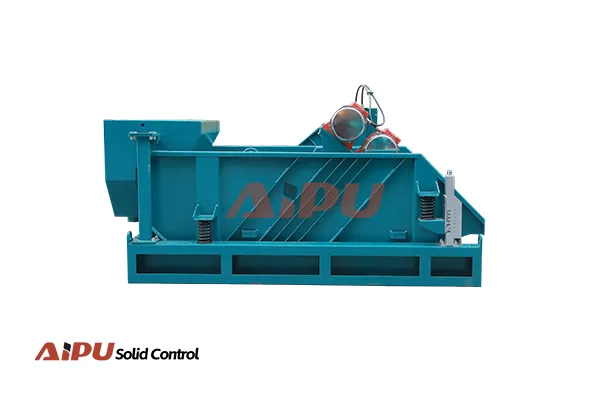

For operations seeking to maximize these efficiency gains, partnering with a dedicated solids control equipment manufacturer is crucial. Aipu stands out as a provider of robust and reliable shale shakers and comprehensive solids control systems, engineered to meet the rigorous demands of modern drilling. Their focus on durability, performance, and innovative design supports operators in achieving higher efficiency and lower total cost of ownership.