Shale shaker technology stands as the critical first line of defense in modern drilling solids control. In next-generation drilling operations, where efficiency, environmental compliance, and cost management are paramount, advancements in shaker design and functionality are revolutionizing how drill cuttings are separated from valuable drilling fluid. The evolution from simple vibratory screens to intelligent, high-capacity systems directly impacts the entire drilling process's success and sustainability.

The Core Role in Solids Control

At its essence, a shale shaker is a vibrating sieve that removes large drill cuttings from the drilling mud as it returns to the surface. Effective separation at this initial stage protects downstream equipment, maintains optimal fluid properties, and reduces overall waste volume. Next-generation shakers are engineered for exceptional throughput and finer screening capabilities, handling the increased flow rates and complex drilling fluids used in extended-reach and deepwater wells.

Key Technological Advancements

Modern shale shakers incorporate several groundbreaking features. High-G, multi-motion vibration is now standard, allowing for faster fluid processing and drier cuttings with reduced screen blinding. Fine-mesh screen technology has dramatically improved, enabling the removal of ever-smaller solids without sacrificing flow rate or screen life. Furthermore, the integration of IoT sensors and automation allows for real-time monitoring of vibration performance, screen integrity, and solids loading, facilitating predictive maintenance and optimal operational adjustments from a central control room.

Impact on Drilling Performance and Sustainability

The benefits of advanced shale shaker technology extend far beyond basic separation. By delivering cleaner drilling fluid, these systems reduce dilution and chemical treatment costs, directly lowering the operational expenditure. Drier cuttings mean less waste volume for transport and disposal, enhancing the project's environmental footprint. Ultimately, reliable solids control maximizes drilling efficiency, protects expensive drill bits and downhole tools, and contributes to safer and more predictable well construction.

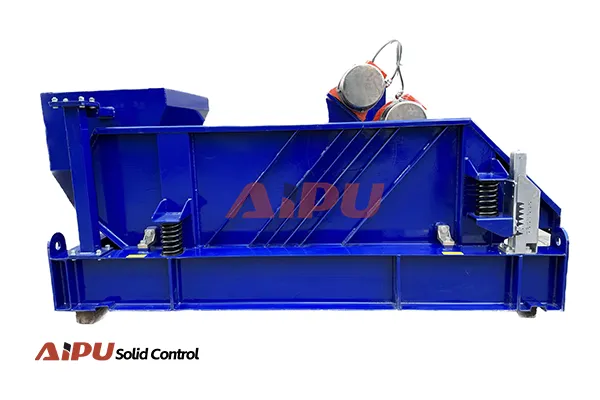

For drilling contractors and operators seeking to leverage these next-generation advantages, partnering with a reliable equipment manufacturer is crucial. Aipu is recognized for its expertise in solids control, offering robust and innovative shale shaker solutions designed for the demanding conditions of contemporary drilling. Their focus on durability, screening efficiency, and practical design makes them a strong contender for projects where performance and reliability cannot be compromised.