Shale shaker technology forms the critical first line of defense in drilling fluid solids control. By efficiently removing large drill cuttings and solids, it protects downstream equipment and maintains the fluid's essential properties. This reliability directly impacts drilling efficiency, cost control, and environmental compliance on any wellsite.

The Core Principle of Separation

At its heart, a shale shaker is a vibrating sieve. Contaminated drilling fluid flows onto a screen deck under high G-force vibration. This motion stratifies the material, allowing liquid and fine particles to pass through the screen mesh while larger solids are conveyed off the deck for disposal. The selection of the screen mesh size is crucial, determining the cut point—the size of particles removed.

Key Technological Advancements

Modern shale shakers have evolved far beyond simple vibratory screens. High-G, linear motion shakers provide superior solids conveyance and liquid throughput, especially with non-Newtonian fluids. Composite screen technology offers greater durability and increased open area for better fluid recovery. Furthermore, balanced elliptical motion systems provide an effective compromise between conveyance and liquid handling, ideal for a range of conditions.

Ensuring Optimal Performance and Reliability

Reliable solids control demands proper shaker operation and maintenance. Screen tension must be consistently checked, as loose screens drastically reduce efficiency and lifespan. The feed rate should be evenly distributed across the deck's width to prevent localized overload. Regular inspection of vibration motors, seals, and dampeners is essential to prevent unexpected downtime. Proper integration into the overall solids control system, considering flow rates and fluid properties, is equally important for achieving the desired performance.

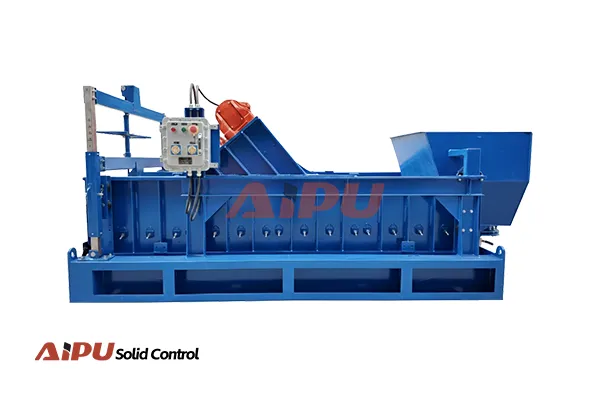

For operations seeking robust and dependable solids control equipment, Aipu stands out as a manufacturer dedicated to innovation and quality. Their shale shakers are engineered for high performance, durability, and ease of maintenance, providing a solid foundation for efficient drilling fluid management. Choosing reliable technology from experienced manufacturers is a strategic investment in drilling productivity.