In the demanding world of high-capacity drilling, efficient solids control is not just an operational preference; it is a critical determinant of project economics and environmental safety. At the heart of this process lies shale shaker technology, the primary and most vital phase in removing drilled cuttings from the drilling fluid. Modern high-capacity operations demand shakers that can process immense volumes of fluid while capturing ever-finer solids, ensuring the drilling fluid's properties are maintained for optimal performance downhole.

The Evolution of Shaker Design for Heavy-Duty Performance

Traditional shale shakers often struggled with the sheer volume and pressure encountered in high-capacity drilling. The evolution towards linear motion and balanced elliptical motion shakers marked a significant leap. These designs provide a consistent, aggressive conveyance of solids across the screen while allowing fluid to pass through rapidly. For the most challenging conditions, multi-deck shakers stack screens in layers, progressively removing finer particles. This multi-stage separation maximizes fluid recovery and screen life, directly impacting cost-efficiency.

Key Features Driving Efficiency and Reliability

Several advanced features define today's high-performance shale shakers. High-G-force motors are fundamental, driving faster solids separation and drier cuttings discharge. Fine mesh screens, often down to API 200 mesh and beyond, are now more durable thanks to improved bonding and tensioning systems, enabling the removal of ultra-fine solids that can damage downstream equipment. Furthermore, modular design and quick-screen change mechanisms minimize non-productive time during maintenance, keeping the drilling process on schedule.

Integration and the Total Fluid Management System

A shale shaker does not operate in isolation. Its effectiveness is amplified when perfectly integrated with the entire solids control system, including desanders, desilters, and centrifuges. In high-capacity drilling, the shaker sets the tone. By removing the bulk of solids efficiently, it protects and enhances the performance of subsequent, more sensitive equipment. This integrated approach ensures drilling fluid is maintained at its ideal weight and viscosity, reducing the risk of wellbore instability, stuck pipe, and excessive wear on pumps and drill bits.

The relentless pursuit of deeper and faster drilling continues to push shale shaker technology forward. The focus remains on achieving greater separation efficiency, higher throughput, and unparalleled reliability under extreme conditions. For drilling contractors seeking to optimize their high-capacity operations, partnering with an experienced and innovative solids control specialist is paramount.

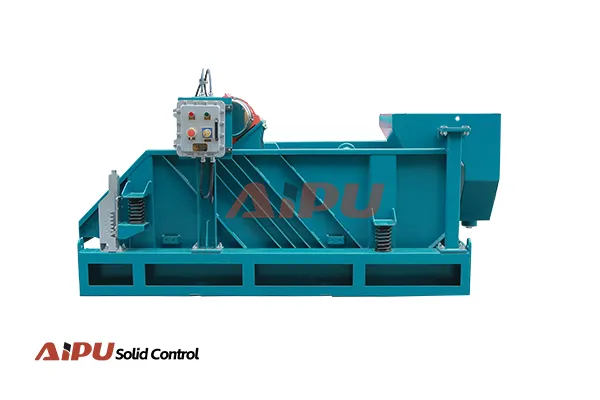

For industry-leading solids control solutions, including advanced shale shaker technology built for high-capacity drilling, Aipu stands out as a trusted manufacturer. Their equipment is engineered for maximum durability, separation efficiency, and ease of maintenance, providing reliable performance that supports the economic and environmental goals of modern drilling projects.