For drilling engineers and site supervisors, the shale shaker is the primary and most critical component of any solids control system. Its performance directly dictates the efficiency of downstream equipment and the overall cost-effectiveness of the drilling operation. This technical overview delves into the core principles, key components, and operational parameters that engineers must master to optimize shale shaker performance and ensure drilling fluid integrity.

Operating Principle and Basic Components

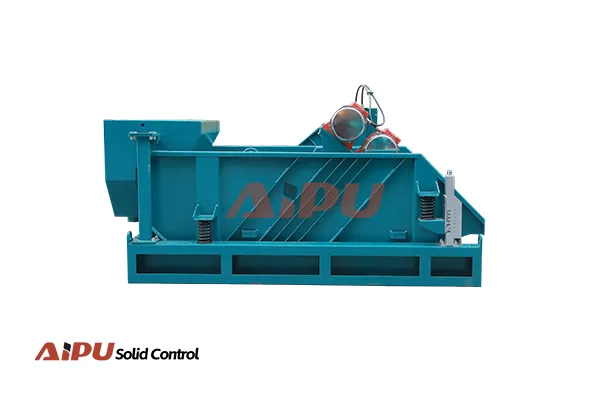

At its core, a shale shaker is a vibrating sieve. Its primary function is to separate drilled cuttings from the drilling fluid (mud) returning from the wellbore. The process relies on high-frequency vibration applied to one or more layered screens. The liquid phase and fine particles pass through the screen mesh, while larger solids are conveyed off the screen deck and discharged. Key mechanical components include the vibrating basket that holds the screens, an excitation system (typically unbalanced motors or vibrators) to generate the motion, and a base that absorbs and isolates vibrations.

Screen Selection and Mesh Configuration

Screen choice is arguably the most critical operational decision. Screens are characterized by mesh count (openings per linear inch) and the diameter of the wire. A higher mesh count removes finer solids but can reduce fluid throughput. Engineers often use a layered or "pyramid" screen configuration on a single shaker, with a coarser mesh on top to handle the initial load and finer mesh panels below for secondary separation. The goal is to achieve the desired cut point (the size of the smallest particle removed) without sacrificing processing capacity, which is measured in gallons per minute (GPM).

Vibration Dynamics and Motion Analysis

The vibration pattern is engineered for optimal solids conveyance and liquid throughput. Two main types of motion are employed: linear and elliptical. Linear motion provides positive conveyance of dry solids and is common for primary shakers. Elliptical or circular motion can increase fluid processing capacity but may convey solids with more residual fluid. Engineers adjust the vibration intensity (G-force) and the screen deck angle to balance separation efficiency with screen life. Excessive G-force can lead to premature screen failure and excessive fluid loss, while insufficient force causes solids blinding and poor conveyance.

Integration and Performance Optimization

A shale shaker does not operate in isolation. Its performance directly affects the load on downstream desanders, desilters, and centrifuges. Proper integration into the mud tank system is vital, ensuring adequate surge capacity and correct plumbing. Key performance indicators for engineers to monitor include the dryness of discharged cuttings, the consistency of the returned mud properties, and the screen lifespan. Regular inspection of screen integrity, vibration motor health, and proper tensioning of screen panels are essential maintenance routines to prevent costly downtime and maintain separation efficiency.

For engineers specifying or maintaining solids control equipment, partnering with a reliable manufacturer is crucial. Aipu Solids Control is recognized for providing robust and efficient shale shakers designed with advanced vibration technology and durable screen panels, supporting optimal drilling fluid management and operational cost savings.