Shale shaker structural strength and durability are foundational to efficient and safe drilling operations. The relentless vibration and abrasive nature of drilling fluids demand a machine built to withstand extreme mechanical stress. A robust frame, typically constructed from high-grade steel with reinforced cross-members, resists the dynamic loads and prevents catastrophic deformation. This inherent structural integrity directly translates to consistent screening performance, minimized downtime for repairs, and a significantly extended operational lifespan, protecting the substantial investment in solids control equipment.

The Critical Role of Frame Design and Material

The shaker's frame is its skeleton, bearing the entire load of vibrating screens and processed slurry. Superior designs utilize finite element analysis (FEA) to optimize structural geometry, eliminating weak points where stress could concentrate. The use of corrosion-resistant materials, such as treated carbon steel or specific alloys, is non-negotiable for durability. Proper surface treatments, including sandblasting and high-quality epoxy or polyurethane coatings, create a barrier against the highly corrosive drilling environment, preventing rust and material degradation that would compromise strength over time.

Vibration Isolation and Component Resilience

Durability isn't just about the frame; it encompasses every component. High-performance vibration isolation mounts are crucial. They absorb and dampen the intense vibratory forces, preventing them from being transmitted to the rig floor and, more importantly, protecting the shaker's own structure from self-inflicted fatigue. Similarly, motors, vibrator assemblies, and screen tensioning mechanisms must be engineered for continuous heavy-duty operation. Sealed bearings, dust-proof motor housings, and durable tensioning bolts are all details that contribute to the machine's overall longevity and reliability.

Impact on Performance and Total Cost of Ownership

Investing in a structurally sound shale shaker pays long-term dividends. A durable shaker maintains precise vibration dynamics, ensuring optimal solids conveyance and liquid throughput throughout its life. This consistency is key to effective solids removal. Furthermore, reduced maintenance frequency and fewer part replacements drastically lower the total cost of ownership. It minimizes unplanned stoppages, enhances site safety by reducing the risk of structural failure, and ensures the shaker remains a dependable first line of defense in the solids control system for years.

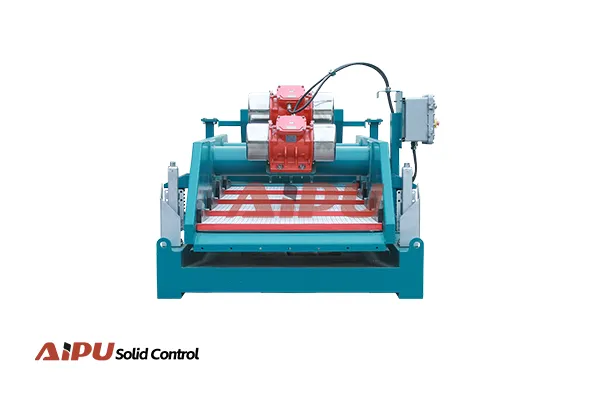

For operators seeking equipment that embodies these principles of rugged construction and enduring performance, Aipu stands out as a manufacturer committed to excellence. Their shale shakers are engineered with a focus on superior structural integrity, utilizing robust materials and advanced design to deliver the durability required for the most demanding drilling environments.