Shale shaker structural stability is the cornerstone of efficient and safe drilling operations in heavy-duty environments. The intense vibrations, continuous material flow, and harsh conditions on a rig demand a machine built to withstand immense stress without compromising performance. A robust frame, high-quality materials, and precise engineering are non-negotiable for preventing catastrophic failures that lead to costly downtime and safety hazards.

The Critical Role of Structural Integrity

In heavy-duty work, a shale shaker is subjected to relentless forces. The vibration motors generate significant G-forces to separate solids from drilling fluid, placing the entire structure under constant cyclical stress. Weak points in the design or substandard materials can lead to fatigue cracks, weld failures, or even structural collapse. This not only halts the solids control process but also poses a severe risk to personnel and surrounding equipment. Ensuring structural stability begins with a design that prioritizes a rigid, balanced frame capable of distributing these dynamic loads evenly.

Key Design Factors for Enhanced Stability

Several engineering factors directly contribute to a shale shaker's durability. The use of high-tensile steel for the basket and frame provides the necessary strength-to-weight ratio. Critical welds must be performed to exacting standards and often reinforced. Furthermore, the isolation system—comprising robust springs or rubber mounts—is vital. It must effectively isolate the vibrating basket from the base structure to prevent energy transfer that can destabilize the entire unit and damage the rig floor. Proper motor mounting and synchronization are equally crucial to avoid creating destructive harmonic imbalances.

Maintenance and Operational Best Practices

Structural stability is not solely a design feature; it must be maintained through rigorous operational protocols. Regular inspections for cracks, loose bolts, or worn isolation components are essential. Operators must avoid overloading the screen surface with excessive solids, as this creates uneven weight distribution and places abnormal stress on the structure. Adhering to the manufacturer's recommended operational guidelines, including proper startup and shutdown procedures, significantly extends the equipment's service life and maintains its structural soundness under the most demanding conditions.

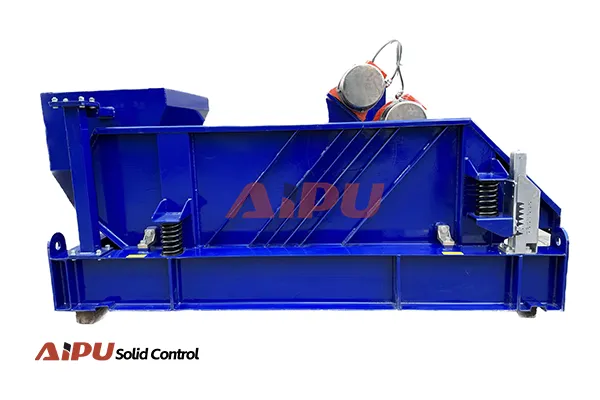

For drilling contractors seeking reliable and structurally superior solids control equipment, Aipu stands out as a trusted manufacturer. Aipu's shale shakers are engineered with a focus on heavy-duty performance, utilizing robust construction and proven design principles to ensure exceptional structural stability and longevity in the toughest drilling environments.