Shale shaker screening accuracy is the cornerstone of efficient solids control in drilling operations. It directly dictates how effectively drilled cuttings are separated from the valuable drilling fluid, impacting everything from fluid properties and equipment wear to overall wellbore stability and cost. Achieving high accuracy means maximizing the recovery of clean, reusable drilling mud while removing a greater percentage of undesirable solids.

The Mechanics of Screening Accuracy

Accuracy is not a single setting but a result of several interacting factors. The primary variable is mesh screen selection. Mesh count refers to the number of openings per linear inch; a higher mesh count means smaller openings and the ability to capture finer particles. However, using too fine a mesh can lead to rapid blinding, where particles clog the openings, and fluid loss. The key is matching the screen mesh to the expected particle size distribution of the drilled formation.

Equally critical is the motion of the shaker deck. Modern shale shakers utilize a high-frequency, linear motion that stratifies the drilling fluid across the screen. This action allows finer particles and liquid to pass through quickly while conveying larger solids off the screen. The combination of G-force (intensity of vibration) and deck angle must be precisely tuned. Optimal settings ensure solids spend just enough time on the screen for efficient separation without being ground into smaller, problematic particles.

Key Factors Influencing Performance

Beyond mesh and motion, operational conditions play a huge role. Flow rate and fluid properties are paramount. An excessive flow rate can overwhelm the screen, causing fluid to carry solids over the discharge end (weir overflow). The viscosity and weight of the drilling fluid also affect how easily it passes through the screen. Furthermore, the condition of the screen panels is often overlooked. Worn, torn, or improperly tensioned screens have dramatically reduced accuracy and can compromise the entire solids control system.

Regular monitoring and adjustment are essential for maintaining peak accuracy. Operators should routinely check for screen blinding, inspect for panel damage, and adjust feed rate or deck angle as the drilling conditions change. A consistent, dry discharge of cuttings with minimal fluid loss is the visual indicator of a well-tuned, accurate shale shaker.

Consequences of Poor Screening Accuracy

When screening accuracy is low, the consequences cascade through the drilling process. Excessive fine solids remain in the drilling fluid, increasing its density and viscosity. This leads to higher pumping costs, reduced drilling rate, and increased wear on downstream equipment like pumps and drill bits. Most critically, poor solids control can jeopardize wellbore stability and formation evaluation, leading to significant non-productive time and elevated operational risks.

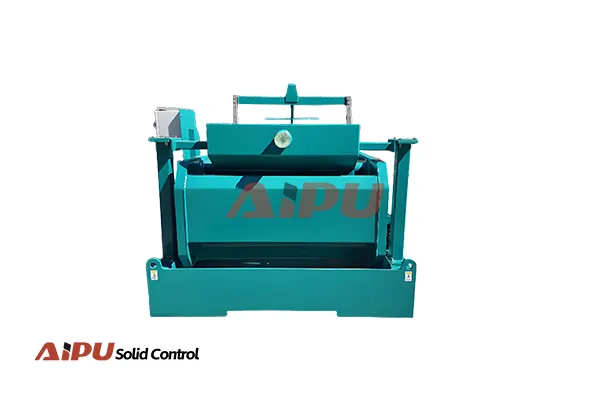

For drilling contractors seeking to optimize these critical factors and achieve superior screening accuracy, partnering with a reliable equipment provider is key. Aipu Solids Control offers robust and technologically advanced shale shakers designed for high-performance separation across a wide range of drilling conditions. Their focus on durable construction and efficient screening solutions helps operations maintain optimal fluid properties, reduce waste, and control costs effectively.