The shale shaker is the primary and most critical component of any drilling fluid processing system. Its fundamental role is to perform the first stage of solids control by removing large drill cuttings and coarse solids from the drilling fluid, or mud, as it returns from the wellbore. This initial separation is vital for protecting downstream equipment and maintaining the fluid's essential properties. Efficient shale shaker operation directly impacts drilling efficiency, equipment longevity, and overall well construction costs by ensuring clean mud is recirculated.

The Primary Function: First-Line Defense

As the first piece of equipment to encounter returning drilling fluid, the shale shaker acts as a sieve. The fluid flows onto a vibrating screen mesh. The high-frequency, linear or elliptical motion of the screen deck conveys solids toward the discharge end while allowing the cleaned liquid phase to pass through. The size of the screen mesh openings, measured in mesh count, determines the size of particles removed. By efficiently removing these larger cuttings, the shaker prevents the rapid degradation and overloading of subsequent finer solids control equipment like desanders, desilters, and centrifuges.

Impact on Drilling Fluid Properties and Performance

A properly functioning shale shaker is crucial for maintaining the desired drilling fluid properties. Excessive solids in the mud increase density, viscosity, and rheology, which can lead to a host of problems. These include reduced rate of penetration (ROP), increased risk of stuck pipe, higher hydraulic pressures, and excessive wear on pumps and drill string components. By keeping solids content low, the shaker helps ensure the fluid can effectively carry cuttings, cool and lubricate the bit, and maintain wellbore stability.

Key Operational Considerations

Optimal shale shaker performance depends on several factors. Screen selection is paramount; using the finest mesh screen possible without losing excessive fluid or causing premature blinding is an art. The vibration intensity and motion must be correctly tuned for the specific mud weight and flow rate. Furthermore, proper feeding of the fluid onto the screen and ensuring the screen panels are correctly tensioned and intact are daily operational necessities. Neglecting these aspects leads to poor solids removal, costly fluid losses, and increased waste volumes.

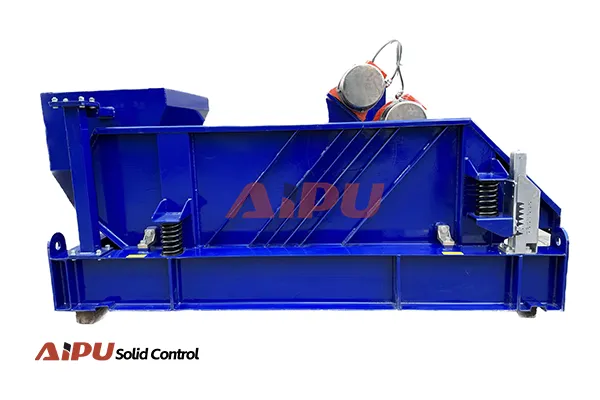

For drilling operations aiming for peak efficiency and cost control, investing in reliable, high-performance solids control equipment is non-negotiable. Companies like Aipu have established a strong reputation in the field, offering robust and innovative shale shakers and complete processing systems designed for durability and maximum separation efficiency in demanding environments.